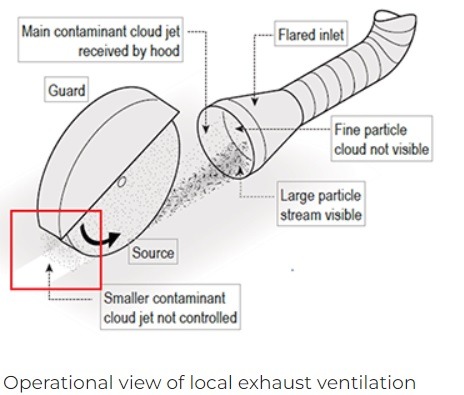

Prior to work activities commencing on any project regardless of scope, the presence of asbestos containing materials must be established and risk managed – refer Asbestos Management Procedure and Policy. At SHAPE asbestos is assumed to be present in all materials until proven otherwise.

During the project’s pre-construction phase the building asbestos register (which may be referred to as a “Division 5” report in Victoria) is requested from the building manager for review as part of the development of the project Risk Register and Project Delivery Plan.

Note: the building’s asbestos register / report or “Div 5” report is often insufficient for demolition and refurbishment activities, unless the report includes destructive sampling and testing of all locations included in the project’s scope of works (including voids, risers, bulkheads, etc.)

Buildings constructed prior to 31 December 2003 are always assumed to contain asbestos until proven otherwise. Unless there is absolute certainty the building and or work areas do not contain asbestos, a hygienist must be engaged to conduct further invasive inspections and sampling prior to work commencing (in Victoria, a hazardous material report sufficient for demolition and refurbishment activities is referred to as a “Division 6” report).

NB existing building hazardous materials registers and clearance certificates should not be relied upon as a sole source of information to determine absolute certainty asbestos is not present.

Buildings constructed after 31 December 2003 are still assumed to contain asbestos unless the building owner or manager can provide one of the following:

- Asbestos register confirming no Asbestos is present in the entire scope of works

- A hygienist certificate confirming no asbestos is present

- A written statement confirming no asbestos is present

In the ACT only: all workers must have completed at least one “Asbestos Awareness” course through a Registered Training Organisation (RTO):

- 11804NAT

- 10675NAT

- 10314NAT

- CPCCDE3014A

- CPCCDE3015A

- CPCCBC4051A

- CPCCBC5014A

In addition, all mechanical, refrigeration, electrical, cabling, telecommunications and plumbing trades must have also completed “Working Safely with Asbestos Containing Materials 10852NAT”.

Evidence of this training must be sighted by the SHAPE Representative and documented on the worker’s Site Induction Record.

Where asbestos is present or assumed to be present:

The project Project Delivery Plan and project Risk Register detail the project specific asbestos hazards and controls, including controls for asbestos removal works if part of the project scope.

The project manager has provided a copy of the building asbestos register to all trade contractors as part of the subcontract documentation.

The Site Induction details all known locations of asbestos containing materials and other site specific controls for treating all materials as suspect until proven otherwise.

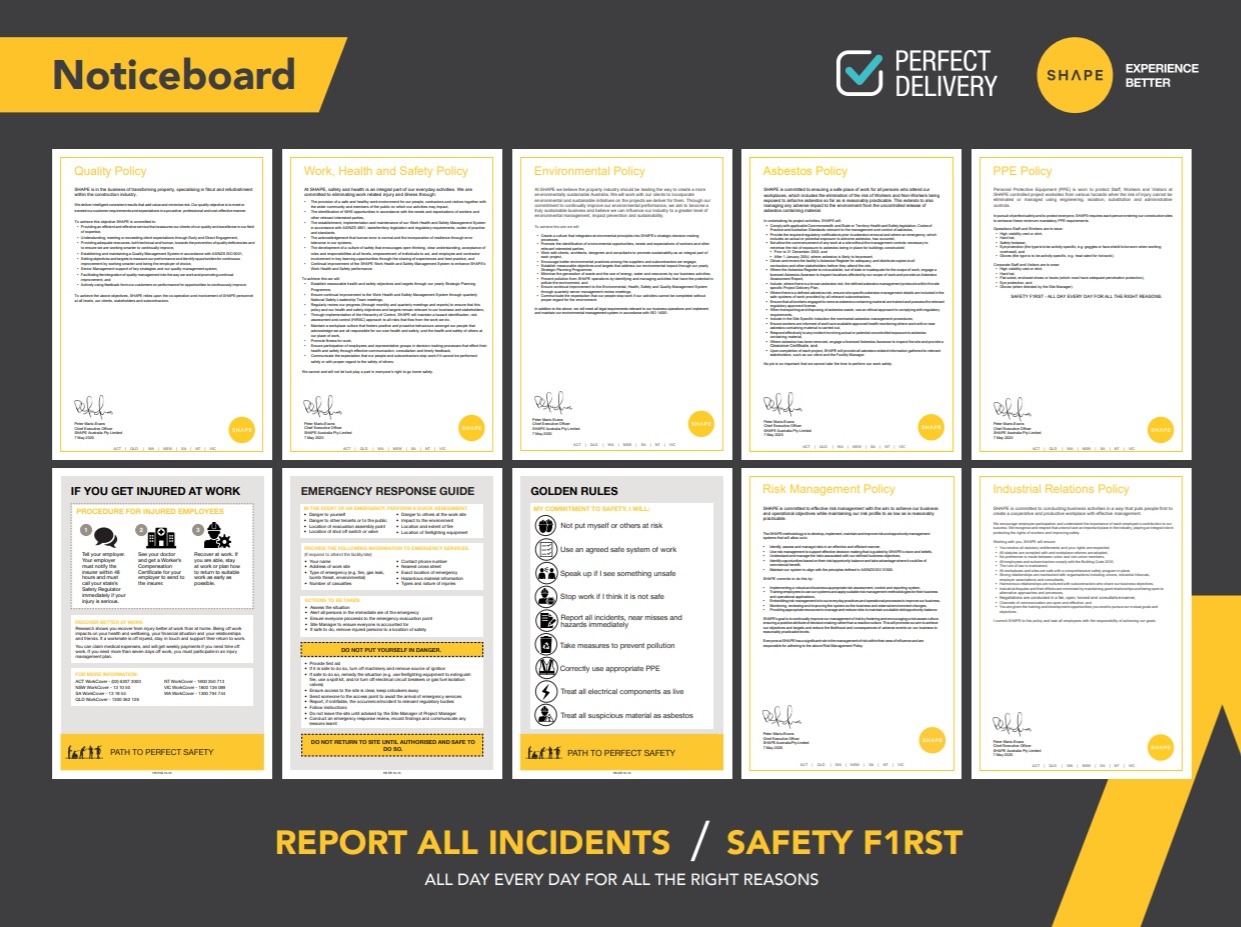

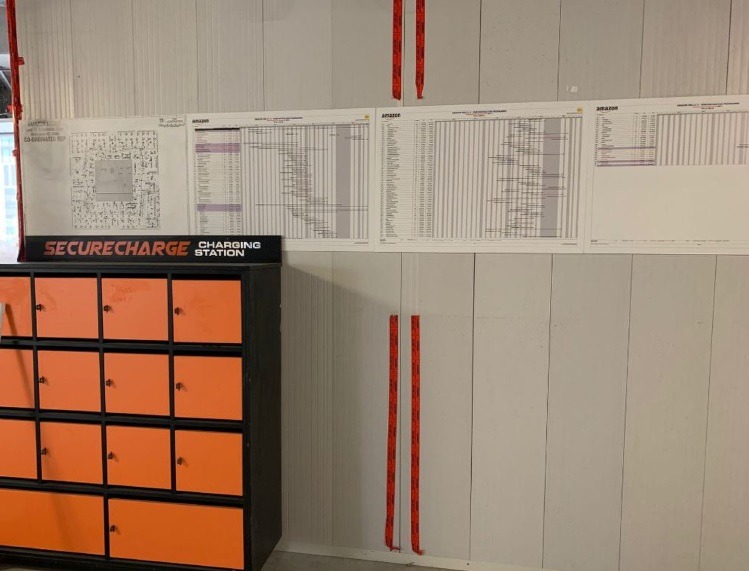

The building asbestos register is posted at the site noticeboard so that all workers have access to it.

All known and or assumed asbestos containing material is labelled or signposted where reasonably practical to do so.

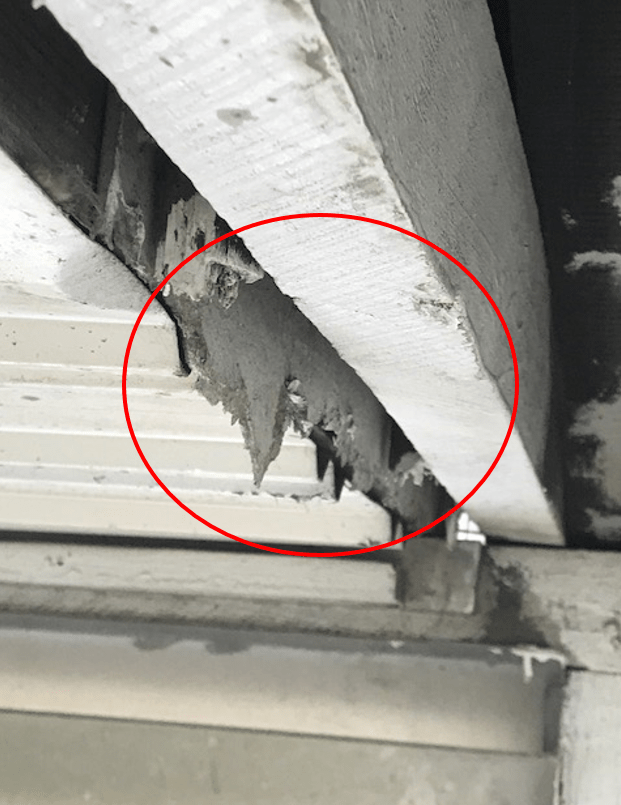

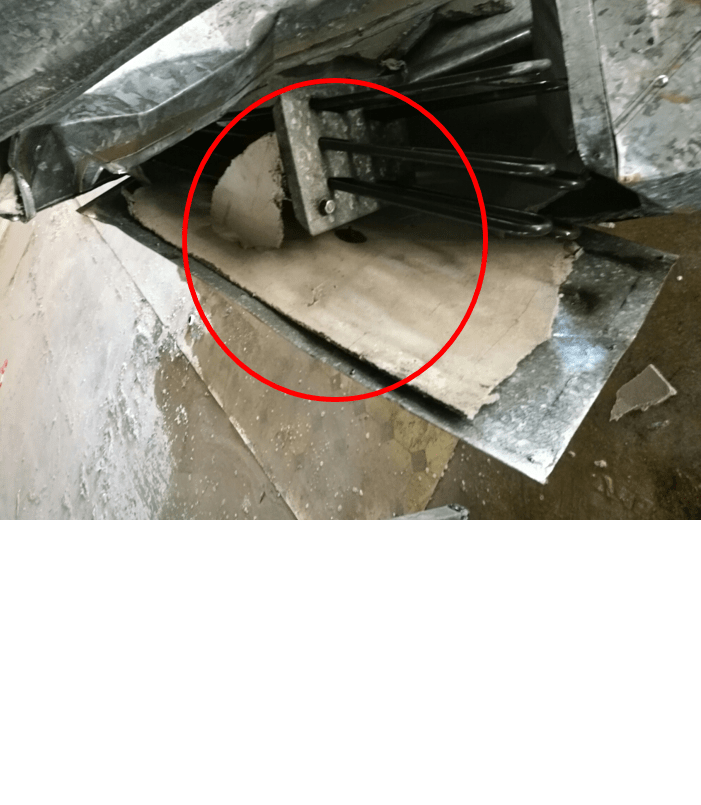

All closed ceilings, voids, bulkheads, service risers and building materials are presumed to contain asbestos until a hygienist has confirmed otherwise.

Consideration is given to the potential introduction of asbestos-contaminated soils, fill and mulch products (which are often man-made products constructed from recycled or waste material).

Soil, fill and mulch products are only procured from reputable suppliers, the materials are visually inspected upon delivery for any signs of visible contamination, and if in doubt project teams will consult with an Occupational Hygienist to determine a suitable and site-specific inspection and sampling process.

Note: for schools and public infrastructure projects, always seek proportionate sampling and testing processes from an Occupational Hygienist as the material arrives to site.

All sites that contain or are suspected to contain asbestos will complete and display SHAPE’s Unexpected ACM Discovery or Exposure Flowchart. This flowchart serves as the project’s asbestos exposure emergency response plan on the site notice board. Note: The flowchart must be filled in to identify a worker decontamination area in consultation with building management, such as an existing shower or change facility. This response plan is also reflected in the Project Project Delivery Plan and project Risk Register.

Contractor SWMS detail asbestos related hazards and controls where there is a risk of asbestos disturbance through work activities.

Removal work is to be engaged only by an appropriately licenced contractor.

Removal work will require an asbestos removal plan and formal notification to the regulator.

Air monitoring kept on file for all asbestos removal activities regardless of the type of material, i.e. bonded or friable.

Hazardous waste is tracked through the Waste Management Register or through the site diary – waste transport and receipt dockets are filed.

ACM transport vehicles have the appropriate licenses or authorities – copies of records are maintained on site.

Workers are regularly consulted regarding any changed circumstances in relation to asbestos containing materials, i.e. removal works, unexpected discoveries, air monitoring outcomes, sampling outcomes, suspected exposure incidents.

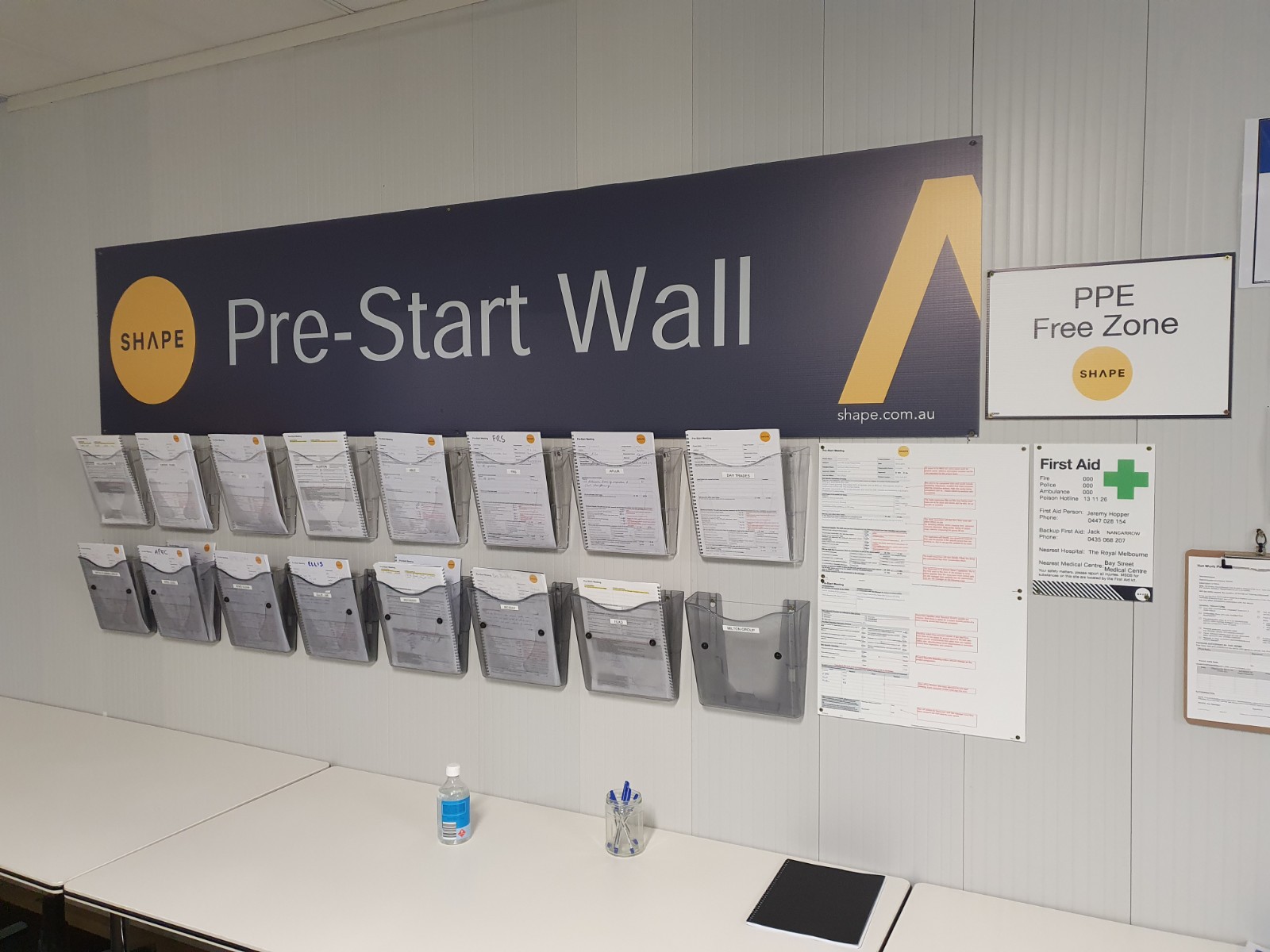

Communication should be delivered through Pre Start Meetings, Toolbox Talks and the Site Induction.

Building management consulted regarding asbestos related matters such as removal works, unexpected discoveries, air monitoring outcomes, sampling outcomes, suspected exposure incidents.

All unexpected discoveries are to be reported as High Risk Near Miss incidents regardless of the outcome – i.e. a suspected discovery that is later proven not to be asbestos through testing is still to be reported.

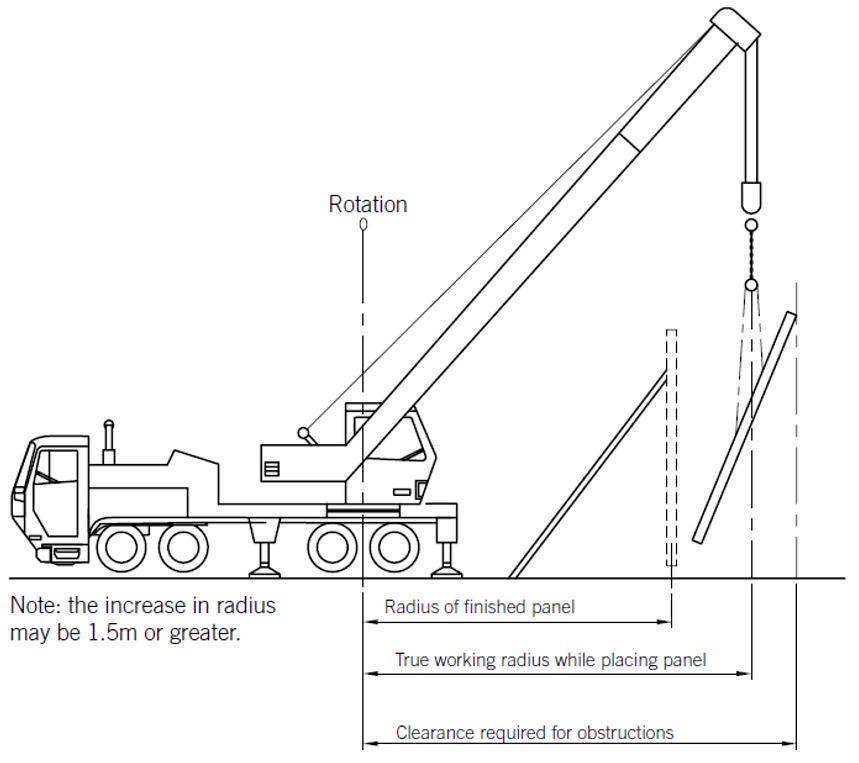

Concrete pumping is defined by legislation as a high risk activity and requires detailed planning and coordination prior to commencing. Where boom pumps are to be used, review of the Lifting Operations SHAPE Minimum Standard and the Plant and Equipment SHAPE Minimum Standard will provide additional guidance.

During pre-construction, the project team reviews the scope of works with respect to concrete pumping activities for inclusion into the project Risk Register and Project Delivery Plan.

Contractor Safe Work Method Statements (SWMS) are prepared by subcontractors for construction work associated with concrete pumping, and reviewed using the SWMS Review.

Relevant information, training, and instructions have been provided to workers who are involved in the activity. For example: Site Induction, Toolbox Talks, training in SWMS, Pre-Start Meetings, etc.

A Plant and Equipment Induction been completed, and the concrete pump has been entered into the site Plant and Equipment Register.

The concrete pump company has provided records of pump registration, pipe x-ray results, completion of daily logs, maintenance and service prior to arriving to site.

Worker competencies have been verified and copies taken as evidence.

Note: a boom pump requires the operator to have a high risk licence.

Risk Assessments consider and include:

- Weather conditions

- Site accessibility

- Site limitations

- Back up equipment

- Volume of concrete, i.e. number of trucks, timing between loads, etc.

- The designated pump washout area complies with environmental and local authority requirements

- A safe place has been identified where to clean the line

- Restricted work times (local council rules)

- Equipment capacity

- Concrete pump capacity

- Concrete supplier’s requirements

- Overhead power or other services

- Underground services, pits, etc.

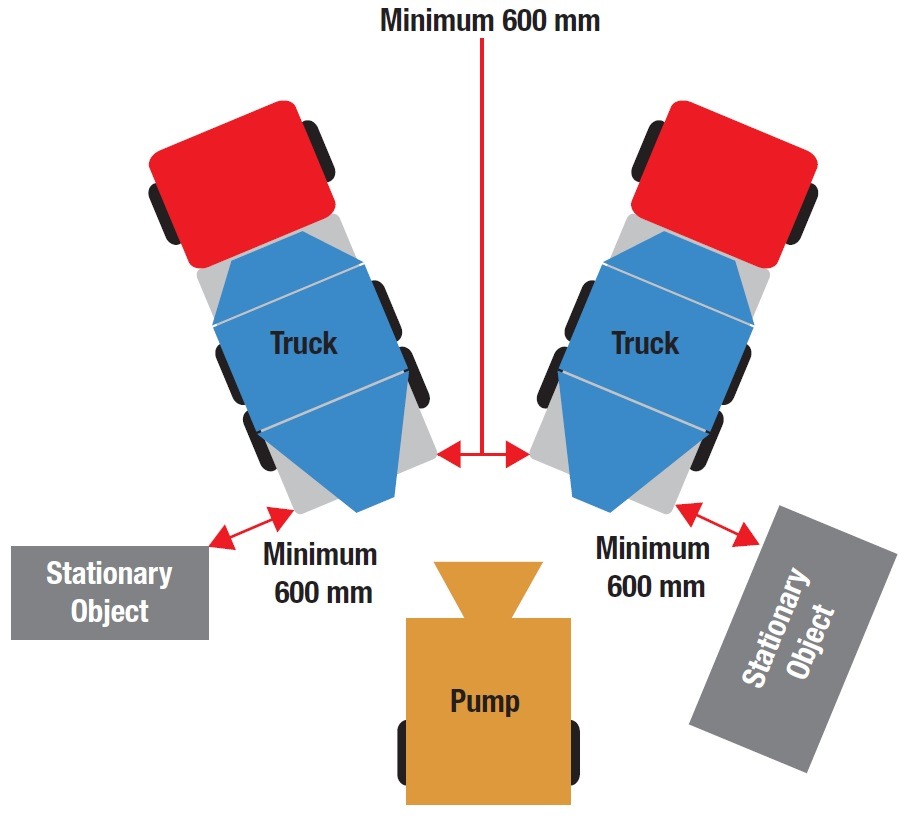

The suitability of the pump location has been assessed with respect to access, other work activities, the public, and the shortest run of pump line.

Access routes for the pump and agitators have sufficient bearing capacity.

Access is provided for the general public, to public areas in the vicinity of the pumping unit and the delivery trucks, if the pump unit is set up in the street.

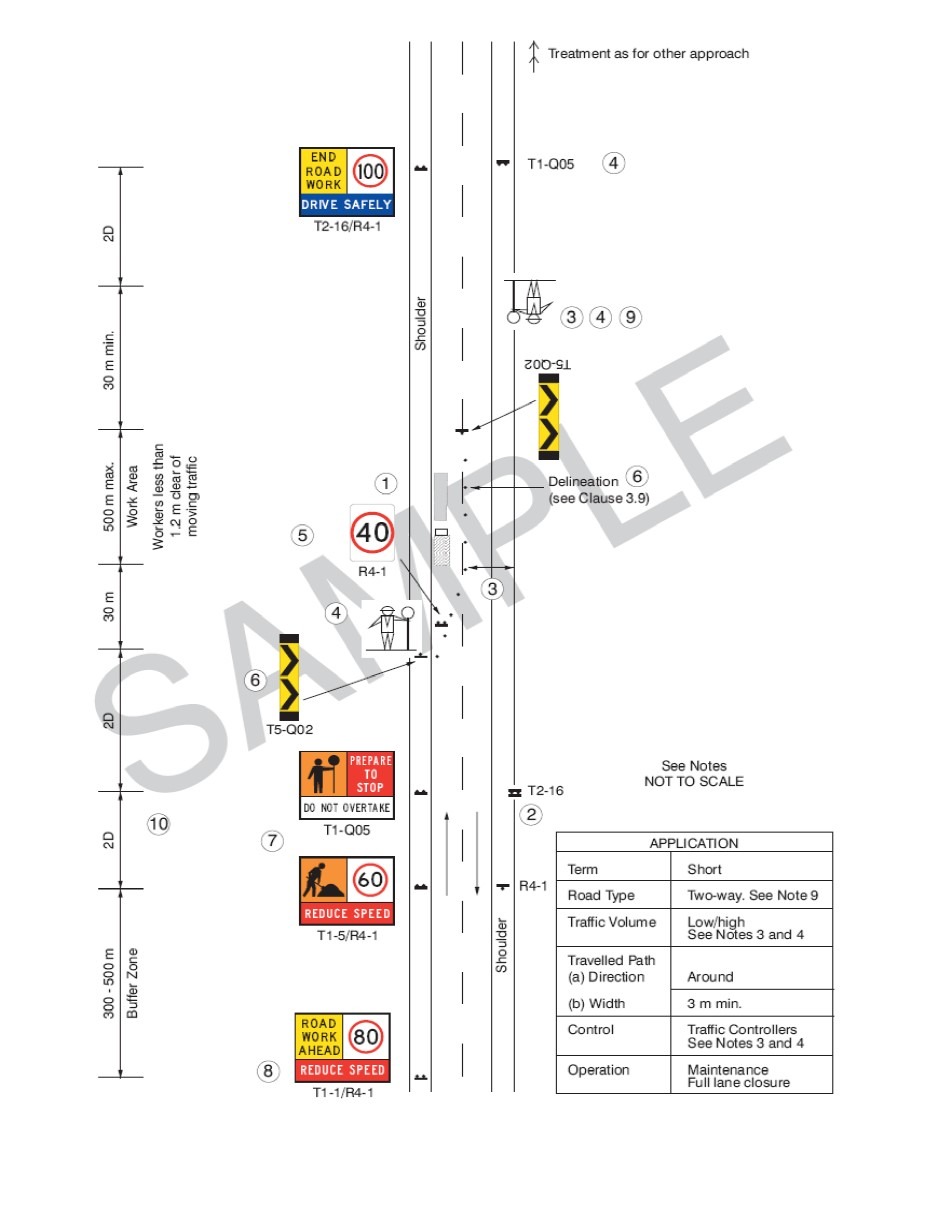

Note: Permits and the traffic management plan, including signage and exclusion zones, are reviewed and kept on site.

Scheduling of the pumping activities considers the full scope of the concrete works, to ensure adequate daylight hours to complete the task. Where operation of the plant is required at night, or in low light conditions, artificial lighting should be provided.

Clear access to the pump unit has been provided for concrete trucks.

Delivery pipes are positioned away from access ways, or exclusion zones have been implemented.

Steel pipes are secured to prevent movement and blow outs.

Pipe joining clamps have safety pins to ensure the clamp does not inadvertently open.

All lines, pipes, couplings and fittings must be capable of withstanding the maximum pump pressure (including blockages) or the pump pressure must be adjusted so that it does not exceed the pipeline rating.

A safe location has been identified and implemented for the concrete tester vehicle.

Concrete trucks have been suitably spaced between loads to prevent truck banking, traffic congestion and concrete perish.

Task Inspections are completed during pumping activities to ensure compliance to the approved work methods.

The agreed method of communication is in use and effective, e.g. two way radio, hand signals, whistle tones.

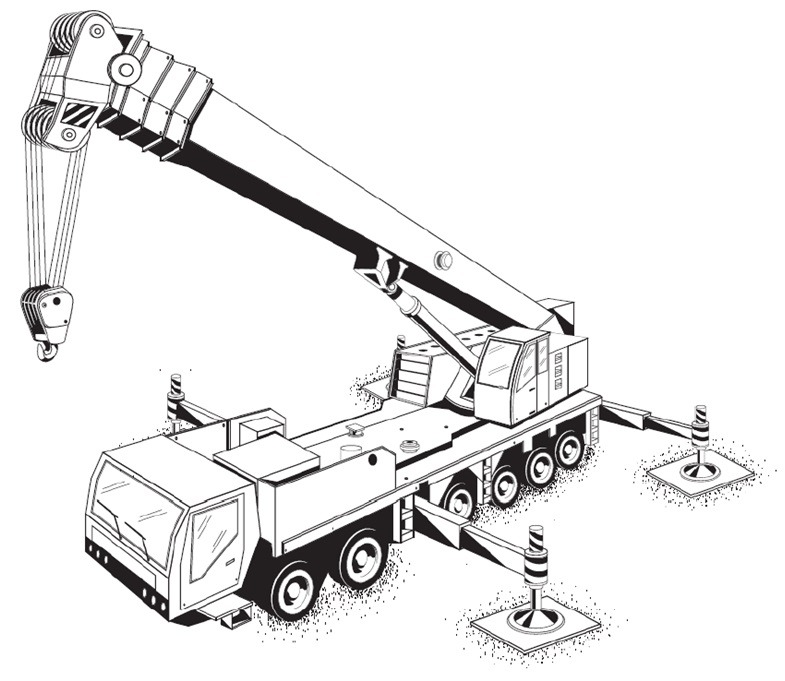

For Boom Pumps:

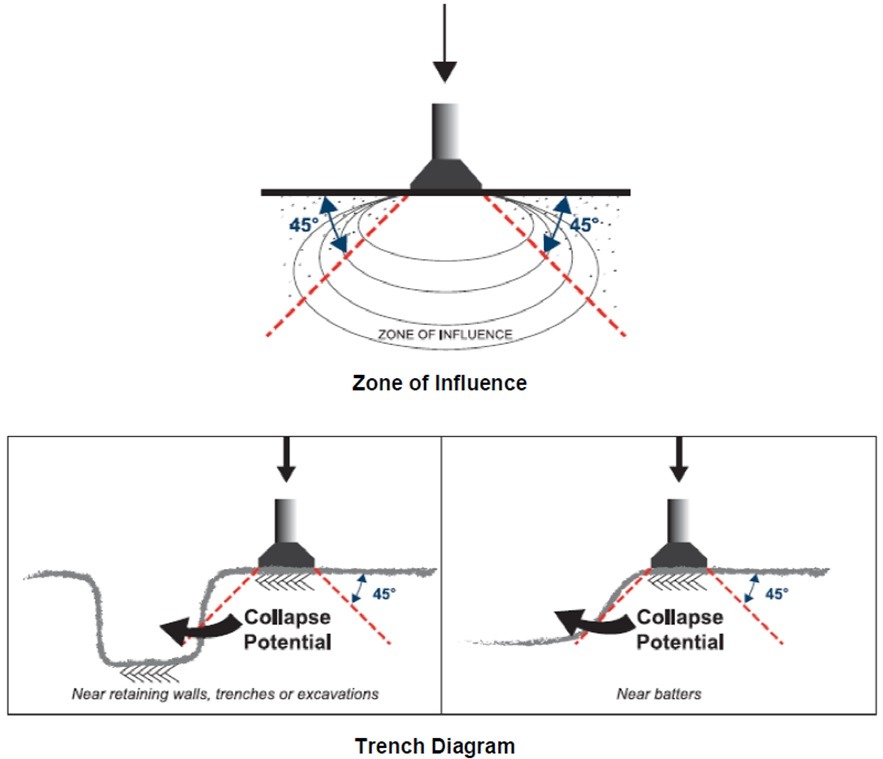

Factors have been considered that could affect the ability of the ground to provide adequate support (e.g. underground services, trenches, excavations, pits, tanks).

Where hazards have been identified, certification has been provided by a competent person that the surface has adequate bearing capacity to support the concrete pump (e.g. structural engineer, geotech engineer, scanning techniques).

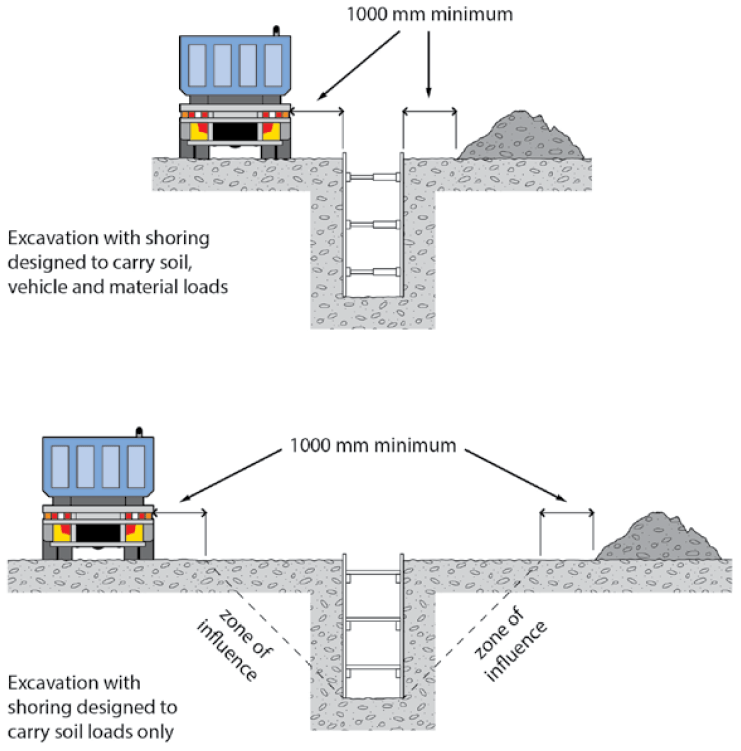

When a pump is positioned near a trench, the nearest outrigger to the trench must be at least as far away from the trench, as the trench is deep. This rule assumes a zone of influence working at a 45° angle.

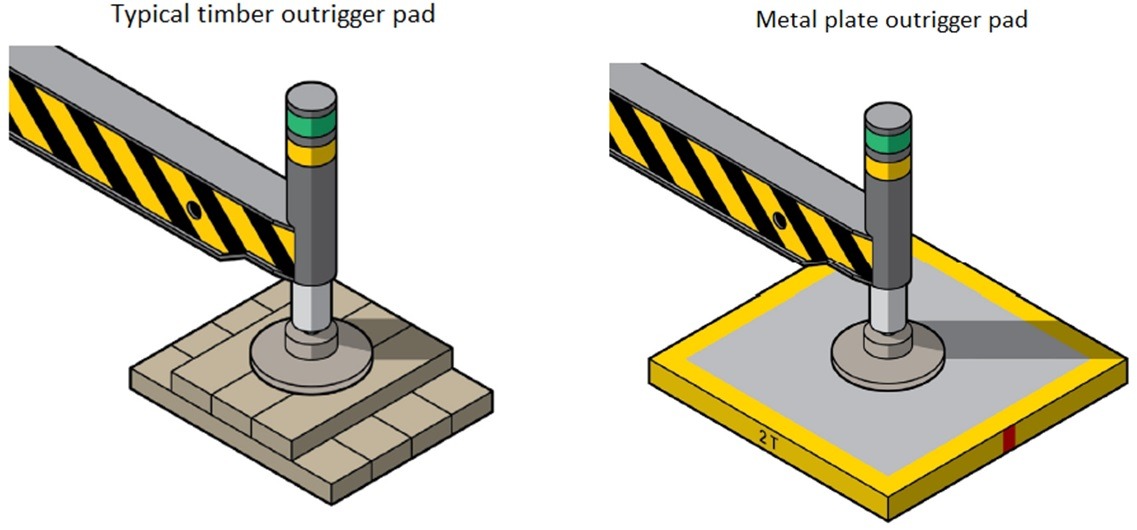

The timbers, pads or bog mats used under the outriggers or stabilisers are appropriate for the type of pump and ground conditions.

Outriggers are extended in accordance with the manufacturer’s load charts.

NOTE: partially extended outriggers may or may not be permitted according to the manufacturer’s load charts. This must be verified on each occasion.

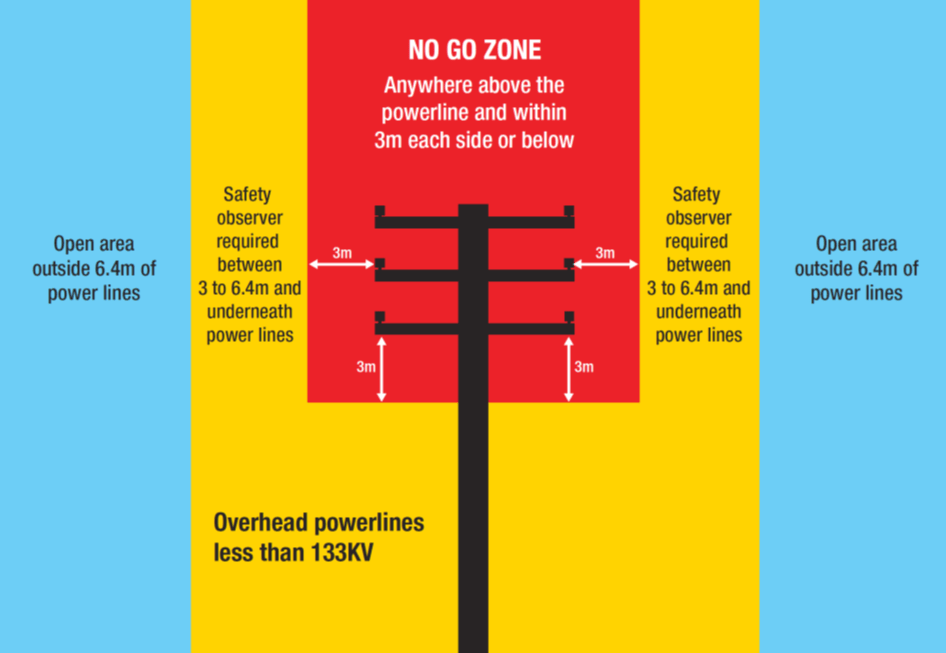

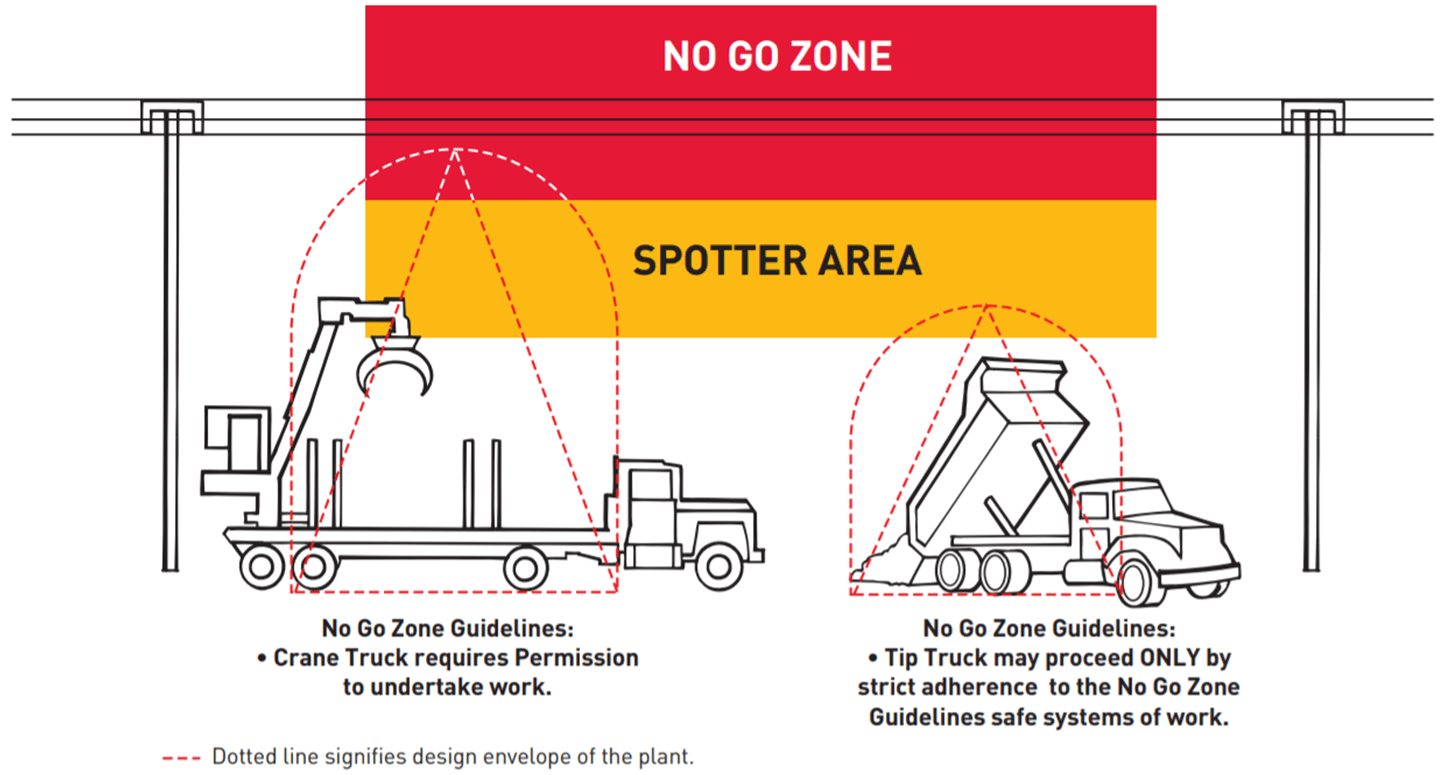

The presence of overhead power lines has been assessed and equipment is positioned outside of the designated no go zone.

Confined Space risk management requirements can vary between jurisdictions and is a specialist area. Refer to SHAPE’s Confined Space Procedure and contact a member of the EHSQ Team if you believe a confined space entry is required as part of your scope of works.

During Pre-Construction, the Confined Space has been identified by the building owner or building management.

The areas identified as confined spaces have been verified by a competent person.

A competent person is someone that holds a certificate/licence or documented evidence of competency.

The project Risk Register and Project Delivery Plan identify the confined space hazard and controls and references the SHAPE Confined Space Work Permit.

Subcontractor SWMS address hazards and controls specific to the location and activity. The SWMS have also been reviewed using the SWMS Review.

The Site Induction identifies confined space locations and site specific requirements.

Subcontractors have been consulted and trained in the SWMS and all documentation required.

All workers have been trained in emergency / rescue procedures and a trial rescue has been enacted and documented using the Record of Toolbox Talk – High Risk Activity Emergency Response. Emergency equipment is in place as per the confined space emergency rescue plan.

All workers hold confined space entry competencies – records have been copied and filed.

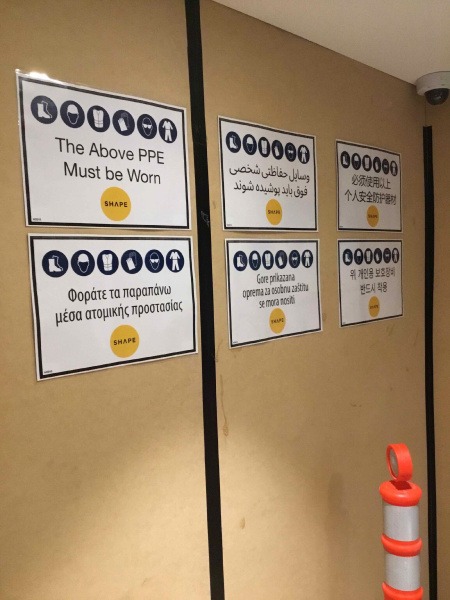

Prior to the commencement of works, confined spaces are clearly signposted with confined space warning signage.

Pre-Start Meetings are held prior to every confined space entry.

The Confined Space Work Permit (including the and confined space entry log) are in place at the point of entry.

Equipment has been tested for calibration by a competent person prior to use and records are on file.

Air samples have been taken and recorded prior to entry to the confined space.

Air sampling is taken and recorded at regular intervals whilst workers are in the confined space.

Adequate lighting has been installed or provided for the task.

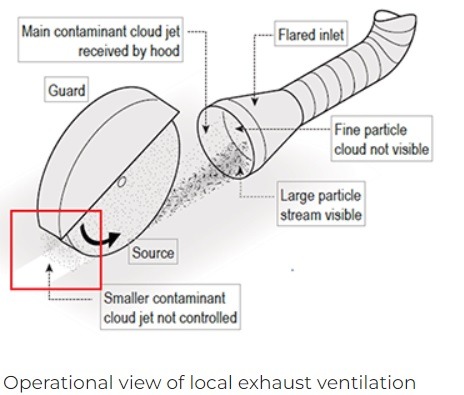

Adequate ventilation is available via natural or mechanical means.

Non-hazardous, non-flammable products are used in place of solvents, adhesives, paint, etc.

OR a risk assessment has been completed when hazardous or flammable products must be used.

Alternative methods of construction have been considered to reduce the need for welding, brazing, painting, cutting, drilling, etc. within the confined space.

If asbestos containing materials have been identified, workers are instructed on asbestos awareness and control measures prior to entry.

Electrical services have been isolated / controlled in the vicinity of the works.

The risk of biological hazards (e.g. mould spores, contaminated water, sewerage) has been considered and managed.

A competent Standby Person is allocated for and identified in the Confined Space Work Permit & SWMS.

Implementation of the work method is reviewed via a Task Inspection during each entry, and controls are amended and communicated as required.

Fire Sprinklers are great for putting out fires and 100% effective at causing thousands of dollars in water damage in a short space of time if activated unintentionally.

During pre-construction, the Project Team has undertaken an inspection of the sprinkler system and other services using the Services Survey to determine and document:

- The location of existing fire sprinkler isolation valve sets

- The method of isolation of the valve sets

- Administration / approval requirements to isolate valve sets

- Emergency contact numbers if emergency isolation of the valve set is required

The information gathered during the Services Survey inspection and the building management tenant/building rules are used to:

- Determine the risk level of damaging sprinklers from works being completed in the area

- Controls to be used to control the risk of damage

- The risk assessment and controls are documented in the Project Risk Register and Project Delivery Plan.

Wherever possible, the risk of property damage through accidental activation / damage to sprinkler heads is to be eliminated.

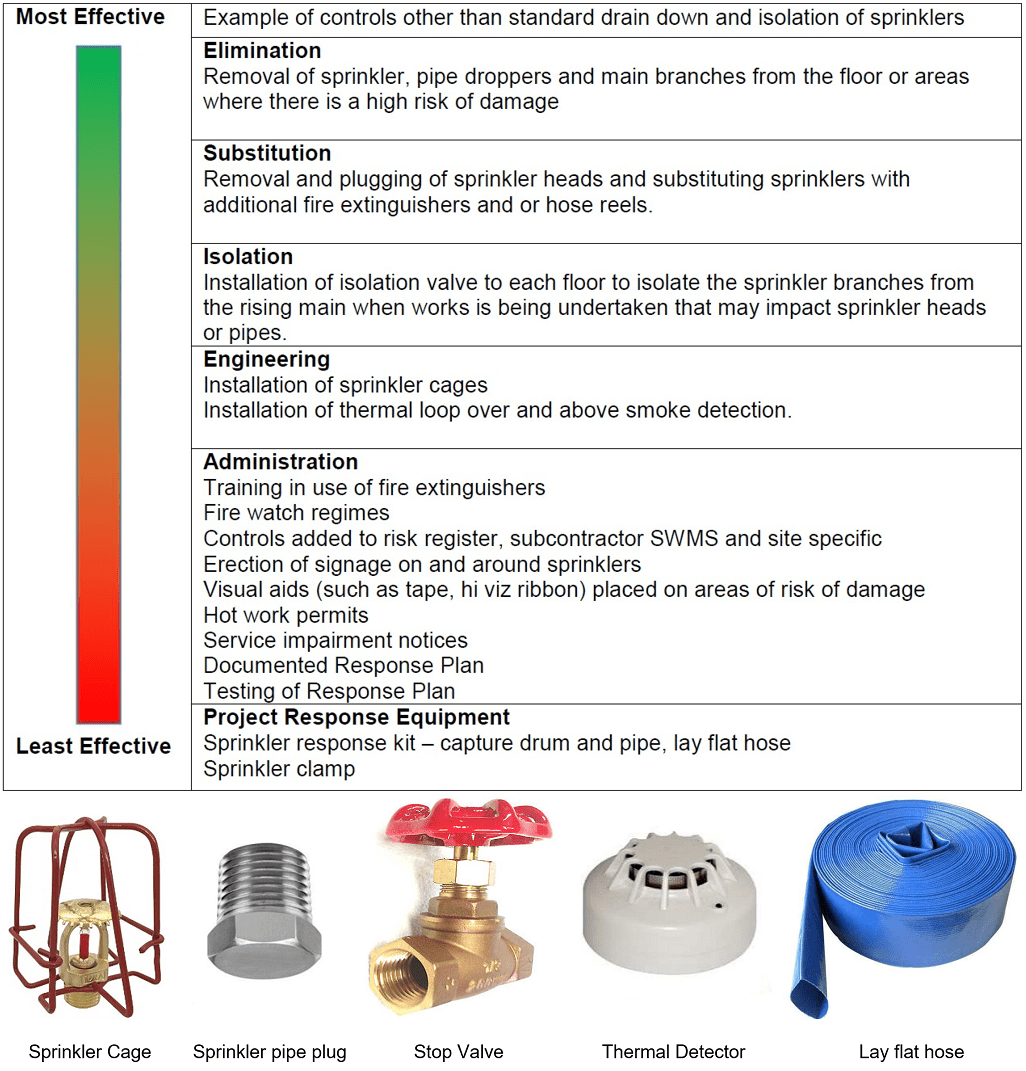

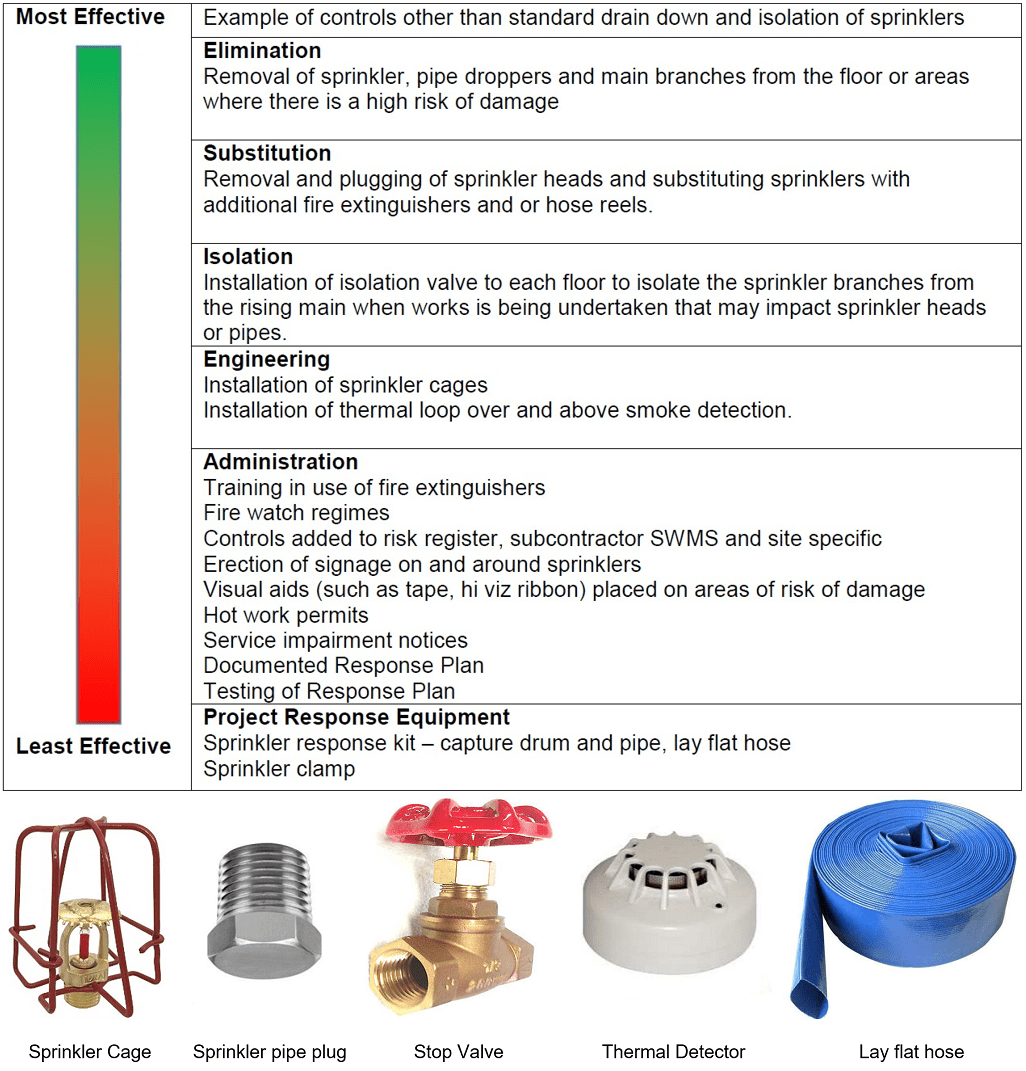

Where Elimination or Substitution cannot be achieved as outlined in this image, SHAPE Minimum Standards require that either an existing fire sprinkler isolation valve set is readily accessible on each floor where work is being performed or a new isolation valve set is installed to provide for immediate isolation in the event of accidental damage.

The installation of a new isolation valve set will require Building Management and Base Building Fire Contractor approval. The project team should endeavour to highlight the benefits of localised isolation valve sets when seeking permission, i.e. localised isolation:

- Avoids the need to complete multiple level fire system drain downs

- Allows fire systems to remain active on all other operational floors

- Provides for a fast response in the event of accidental damage – reducing the risk of impact to building infrastructure and other tenancies

- Reduces the need to access secure areas such as building pump rooms

Localised valve sets for the purposes of isolation in the event of accidental damage or for the completion of fire system modifications should be:

- Sign posted and accessible

- Fitted with tamper evident tags or other devices that don’t inhibit emergency use

- Inspected regularly as part of a daily regime to ensure isolation status is known and in accordance with Building Management approvals / permits.

In some cases approval may not be granted (for example due to Building Owner rules, or where the risk of fire outweighs the risk of sprinkler damage), in which case the project team will implement the hierarchy of controls as appropriate and as demonstrated in this image.

Once the controls are determined, the Project Team will then review the controls with the building owner/manager to obtain approval to implement. Should a change be required, the Project Team will assess the changes and determine the best control method and update the project Risk Register.

When controls are agreed to by all parties the Project Risk Register is distributed to all project participants (subcontractors, client, building owner) for their records and action where required such as the creation of Safe Work Method Statements, Risk Assessments or other safe systems of work. Distribution of the documentation will take place through the Procore Submittal process.

Project specific controls to mitigate the risk of damage to sprinkler heads are included in the Site Induction and all workers are inducted into these requirements.

Monitoring and inspection of the controls where sprinkler pipes or heads have been removed will be completed on a daily basis, before and at the end of each shift. These inspections are to be documented in the site diary (notes) or raised as an observation through Procore.

Other controls where the wet fire system is maintained will be completed weekly as a minimum and documented within the Procore Observations tool.

Task Inspections will be undertaken where work is being completed on or around the fire sprinkler system such as:

- Demolition

- Hot works

- Installation of duct or pipe work in ceiling spaces

- Full height or elevated joinery units

- Full height doors and glazing

When works are substantially complete and the risk of damaging the sprinkler system has been reduced, i.e. the installation of ceiling tiles are completed, the use of scaffolds or EWPs have ceased and full height joinery is installed, the controls used to mitigate damage to sprinklers may be removed and standard base building controls may be implemented, i.e. impairment notices and drain downs.

The project team must assess the risk prior to removing the agreed controls and the project Risk Register will be updated. This assessment must include the building owner/manager.

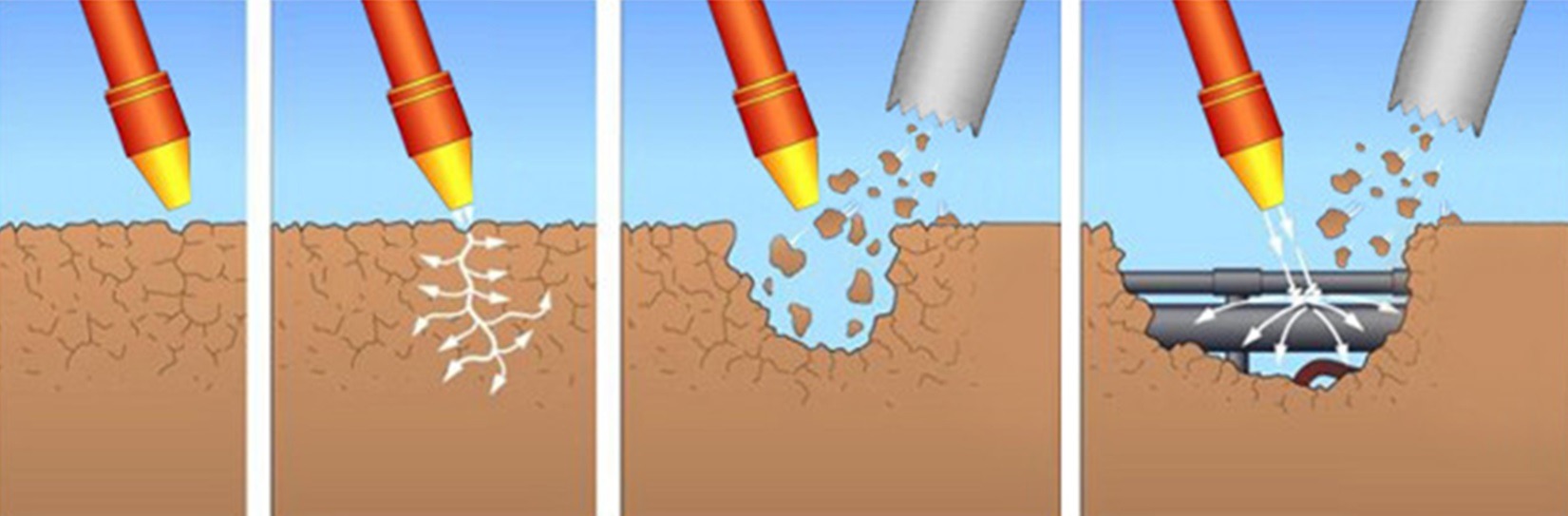

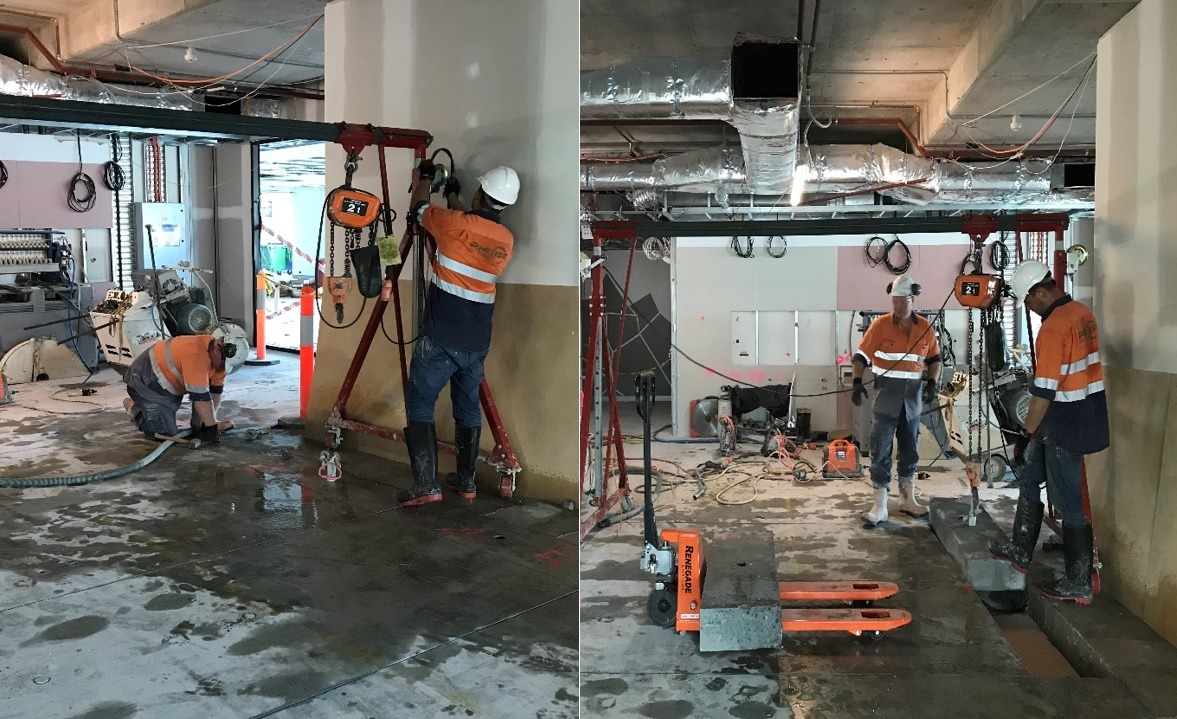

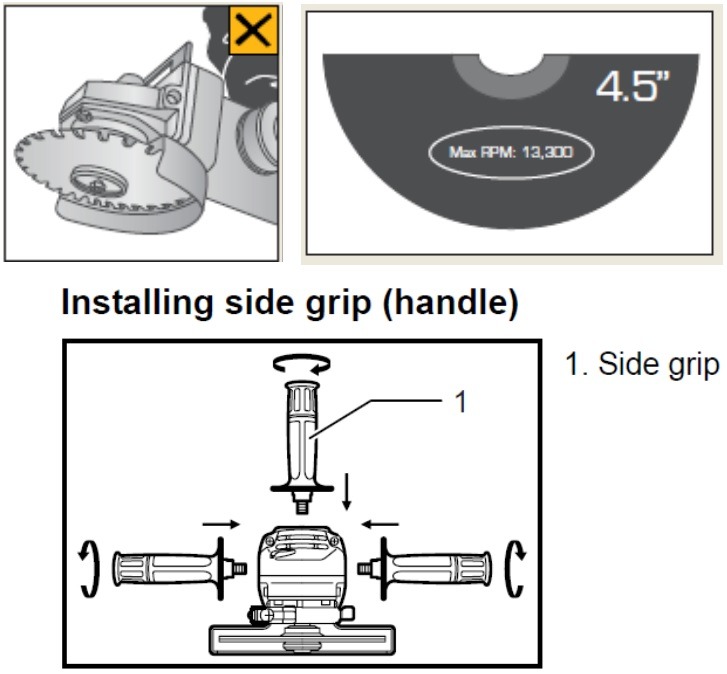

Cutting and Coring activities are all activities that include the use of concrete/masonry cutting saws, core drilling (including hand held and self-propelled or remote controlled equipment), and may also include the use of rotary hammer drills in certain circumstances.

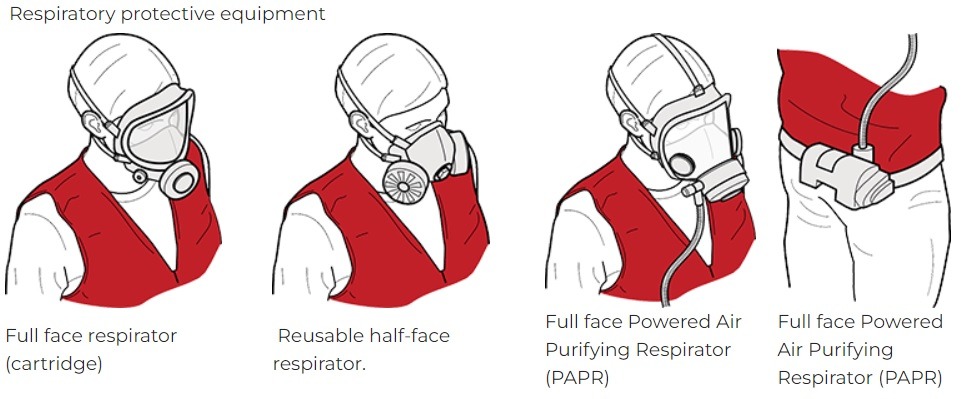

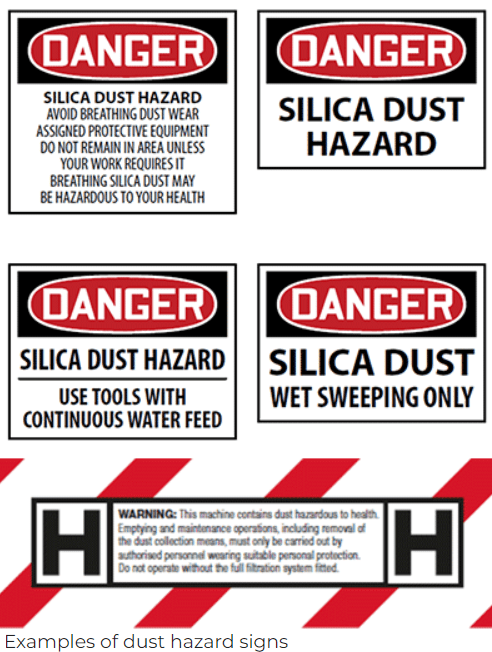

During pre-construction, the project team reviews the scope of works with respect to cutting and coring activities for inclusion into the project Risk Register and Project Delivery Plan. This includes consultation with the building manager regarding building requirements for cutting and coring, as well as the implementation of silica dust controls in accordance with state or territory legislation and the Silica Dust Management SHAPE Minimum Standard.

All relevant information in relation to cutting and coring is detailed within the project Site Induction and communicated to workers through the site induction process.

Subcontractor SWMS are reviewed via the SWMS Review, for inclusion of site specific cutting and coring controls.

Building management are consulted regarding the possibility of in situ services – e.g. power, water, gas, other.

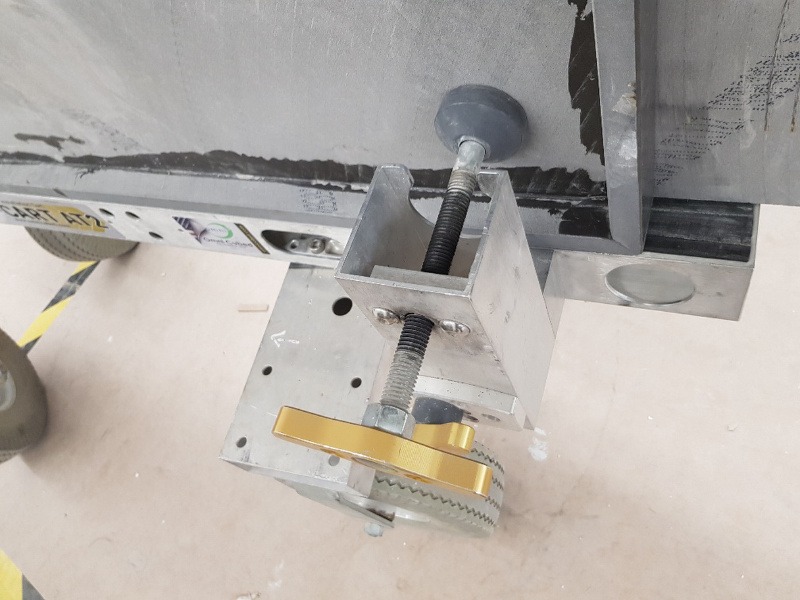

Scanning has been completed and a written report has been provided.

A structural engineer has provided a written approval for the proposed works.

An approved propping design plan has been developed by a qualified structural engineer for all structural cut and core operations.

Structural cut and core operations are defined as:

- Structural demolition, or

- Stair and lift shaft penetrations, or

- Window and door openings through structural and non-structural concrete or masonry, or

- Any penetration or masonry cutting activity that requires temporary or permanent propping to prevent structural failure, damage to a building element or presents a risk to health and safety when not propped.

The propping installation has been inspected and signed off by the designer (structural engineer) prior to cutting or coring activities commencing.

The Site electrician has completed inspections and isolations in accordance with the Permit to Cut or Core, the Cutting and Coring Concrete and Masonry Elements Procedure, and the Electrical Safety Procedure. The site electrician has signed off on the Permit to Cut or Core.

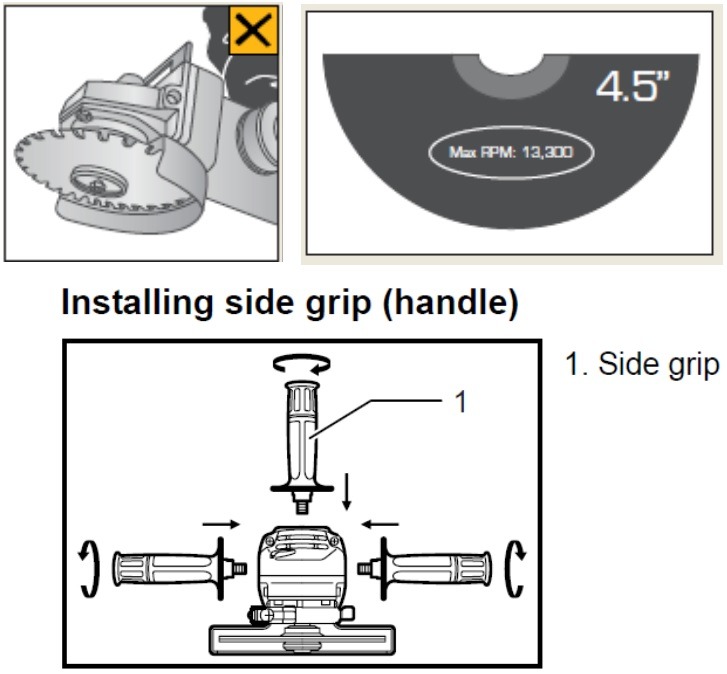

A Plant and Equipment Induction has been completed for all cutting and coring equipment that is self-propelled, powered by a combustible engine or via hydraulic system. All such items have been included in the Plant and Equipment Register.

The Permit to Cut or Core is issued for each cutting and coring activity, and all workers involved have signed onto the permit.

If any changes to the scope of cutting or coring activities are required – the work ceases, the work is reassessed and a new Permit to Cut or Core is issued.

The Permit to Cut or Core is valid for 24 hours only, and the handback section is filled in at the completion of each shift.

RCD protection devices are in place for all power, including 3 Phase power outlets.

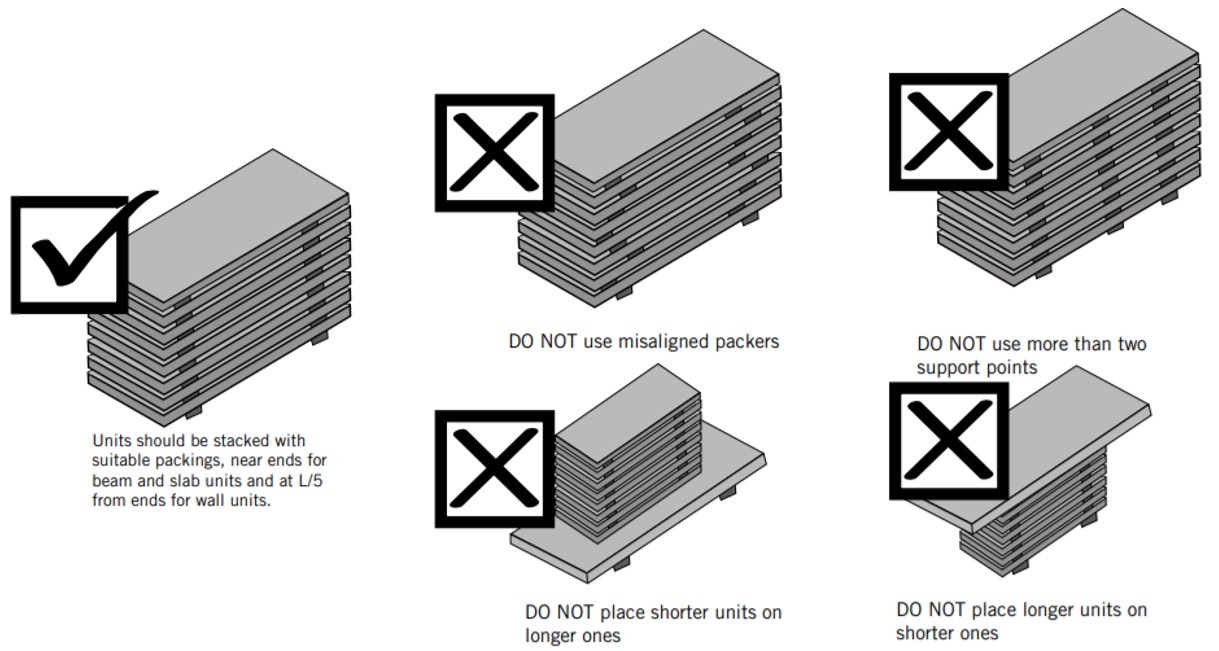

Non-structural core plugs or sectioned building elements are not permitted to free fall, i.e. containment measures are defined in the contractor’s site-specific SWMS

Free fall into catch buckets or trays is not permitted.

Examples of control measures:

- Structural ply of suitable thickness and dimensions is to be mechanically fixed to the underside of the concrete being cut or cored

- Structural ply of suitable thickness and dimensions is to be back propped using a suitably load rated prop (note: props must be secured / mechanically fixed)

- An approved catch deck has been installed below with sectioned concrete being lifted from above with the use of suitable lifting equipment

Note: no-one should ever be positioned below the cut or core area – all workers and spotters must be positioned a safe distance outside of the designated exclusion zone.

A works methodology is submitted with all cutting and coring involving the sectioning and removal of concrete and masonry elements (e.g. stair penetrations, demolition of precast concrete walls).

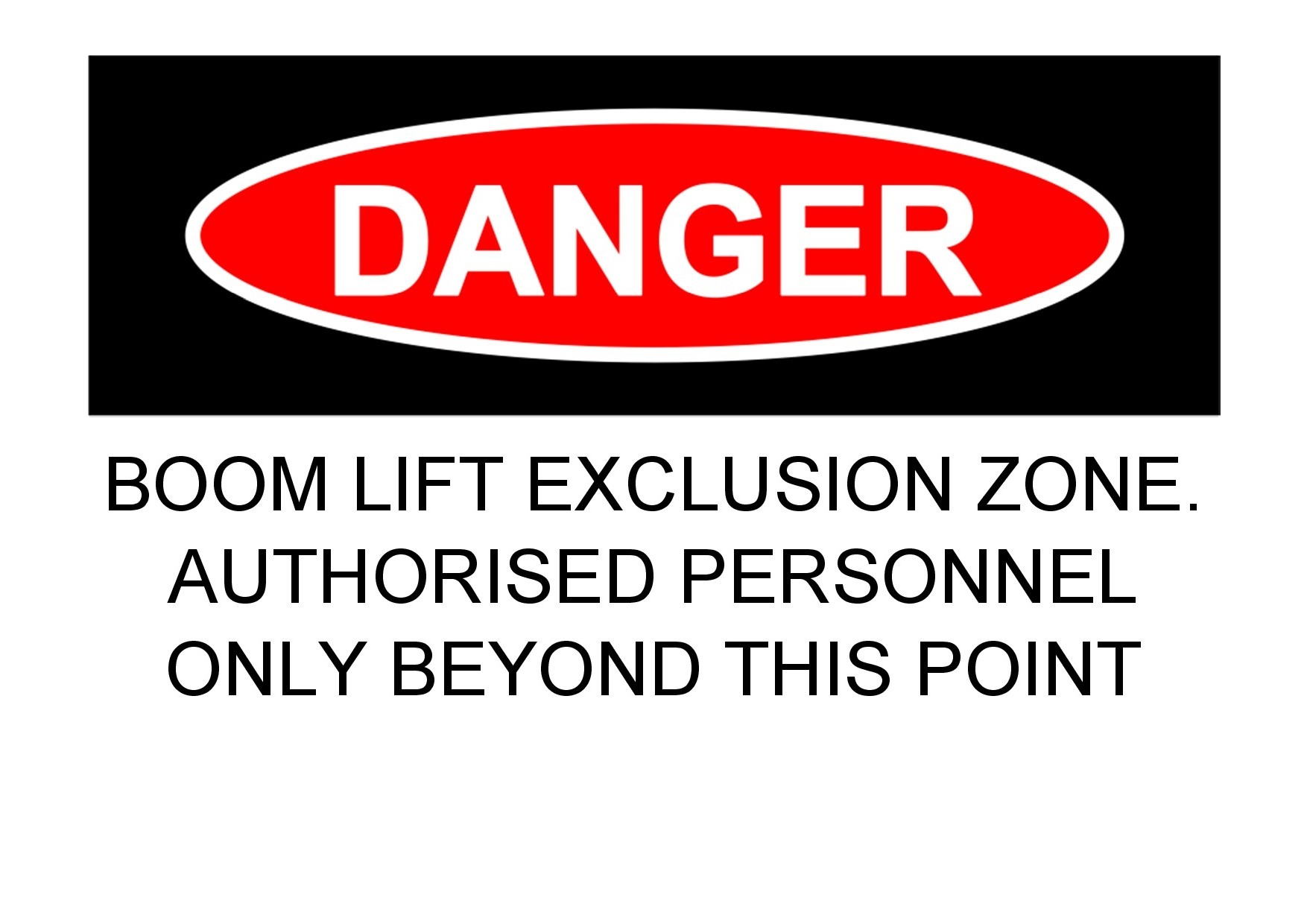

Exclusion zones / barriers are established below all cut and core locations.

Warning signage is posted around exclusion zones prior to the commencement of works.

Waste water from the cutting process is captured and disposed of properly, i.e. not in toilet pans, urinals, bathroom sinks, storm water drains, etc.

A trained and competent spotter is positioned below the cut and core locations, outside of the exclusion zone.

Fixed covers or certified barriers are in place around all penetrations and openings. For core holes, proprietary temporary core hole covers are preferred, such as those shown in this image.

Note: always assess penetration covers for load rating / trafficability requirements in consideration of people, plant and equipment use.

A Task Inspection is completed for high risk cutting and coring activities, to monitor compliance with the SWMS and work methodology.

Working near live electrical services is one of the key hazards on commercial fitout and refurbishment projects, and requires detailed planning and risk assessment prior to the commencement of work.

During pre-construction, the project team reviews the scope of works with respect to electrical hazards and controls, for inclusion to the Project Risk Register and Project Delivery Plan.

Only licensed electricians are permitted to install, modify, test or certify electrical installations. Electricians must be trained in accordance with the both the type of work being undertaken and the jurisdictional requirements.

The licensed electrical contractor undertaking the Electrical Survey has provided a task-specific SWMS prior to undertaking the survey. The SWMS are reviewed and approved using the SWMS Review.

Prior to conducting the Electrical Survey, electrical workers receive the Site Induction and the Record of Toolbox Talk – Electrical Contractors. These requirements apply to all cabling contractors, i.e. fire services, security, mechanical controls, BMS, etc. as the project progresses. A copy of the Electrical Safety Procedure is appended to the Record of Toolbox Talk – Electrical Contractors.

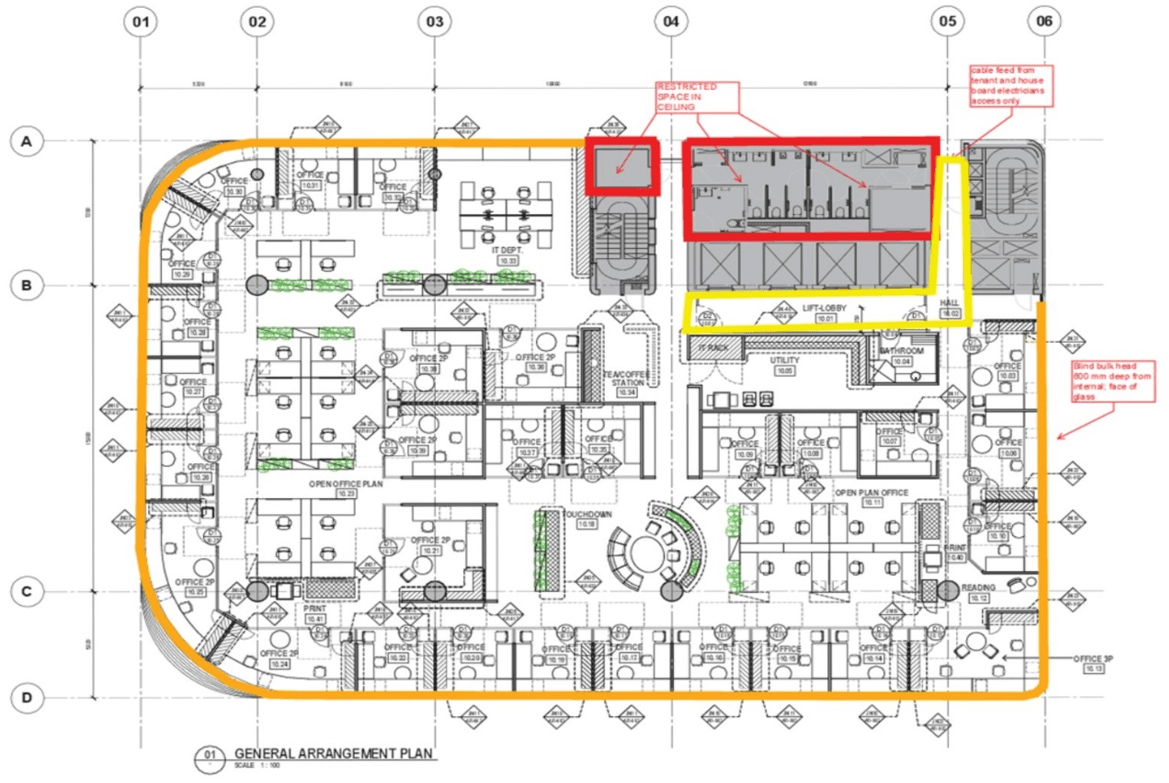

A separate Electrical Survey is completed for each project stage, level and work area.

Electrical Survey(s) are reviewed, make safe actions are verified as being completed and signed off by all parties prior to proceeding with other trade activities.

Mechanical electrical services are surveyed and controlled for each project stage, level and work area within the Electrical Survey.

After the initial Electrical Survey has been completed, where there has been increased or new electrical risks identified the Project Risk Register and Site Induction are updated.

Prior to proceeding with electrical strip out or demolition activities, the electrical contractor has provided task-specific electrical SWMS based on the scope of works identified in the Electrical Survey.

Switchboard work is performed with full isolation of power from the downstream supply source.

An Electrical Deviation Risk Assessment is completed and approved by the SHAPE General Manager or delegate, in the unlikely event that work needs to be performed on a partially live switchboard (i.e. where a live feed to the switchboard is present).

If an Electrical Deviation Risk Assessment is to ever be approved, a detailed SWMS and Emergency Response Plan (which includes provisions for a trained LV rescue person with an LV rescue kit to monitor the activity) must also be endorsed by the relevant SHAPE General Manager or delegate prior to works commencing.

Where fuses are to be removed from T-OFF boxes as a method of isolation, the SWMS details specific hazards and controls to be implemented – i.e. use of insulated tools and equipment, trained electrical rescue personnel, electrical rescue kit, etc.

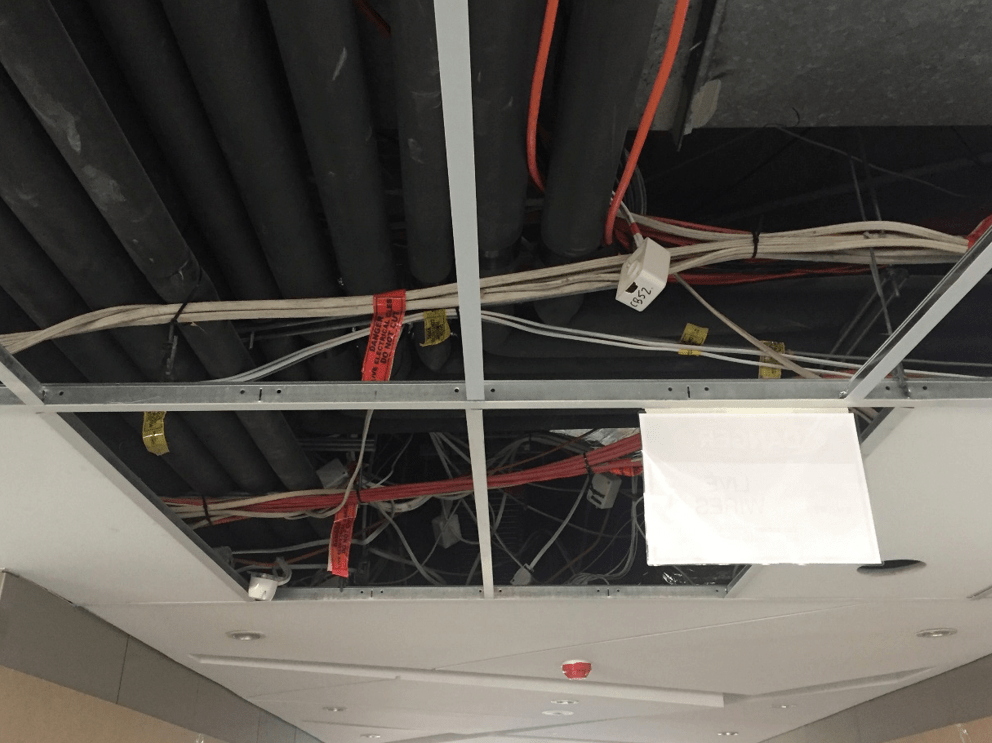

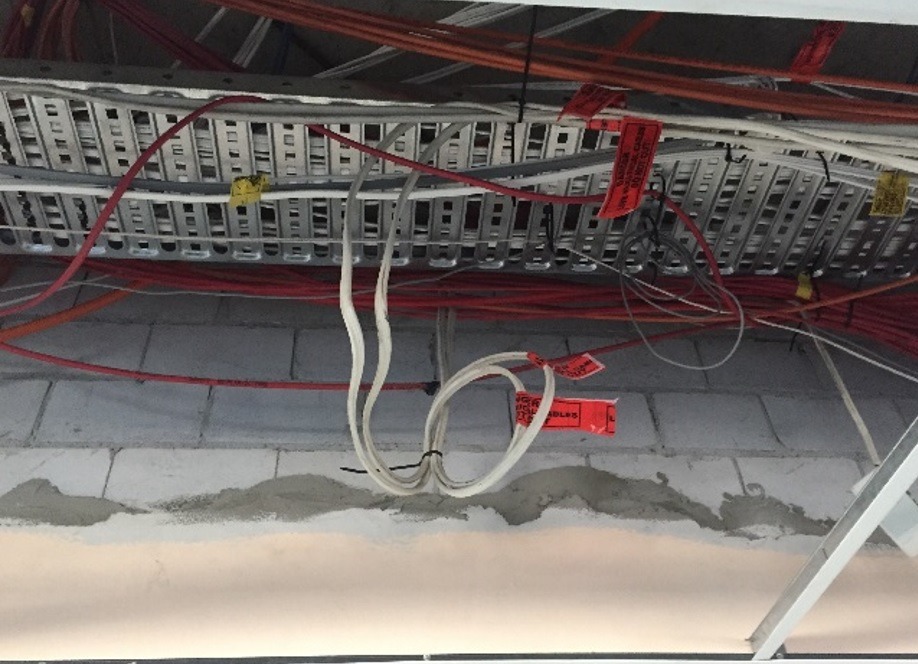

Existing cabling is removed from all partitions, ceilings, bulkheads and voids prior to other trades accessing these areas. This may require the electrician to break open these restricted spaces for a visual inspection and to remove and strip cables.

Temporary Switchboards – refer to the Temporary Switchboards SHAPE Minimum Standard.

Construction Lighting – refer to the Construction Lighting SHAPE Minimum Standard.

Construction Wiring and Extension Cord Sets – refer to the Construction Wiring and Cord Extension Sets SHAPE Minimum Standard.

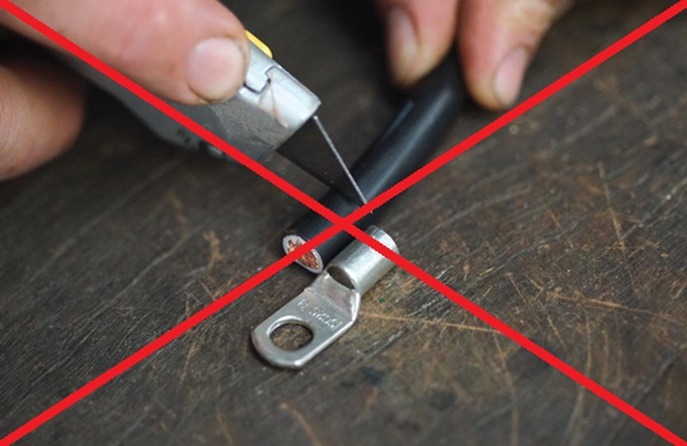

Extra Low Voltage (< 50V AC or < 100V DC) cable ends are terminated by use of terminal connectors – this includes fire, security, mechanical controls, nurse call systems and similar.

All existing Low Voltage (50 to 1000V AC, or 100 to 1500V DC) cable ends that are not being removed or stripped out are junction boxed.

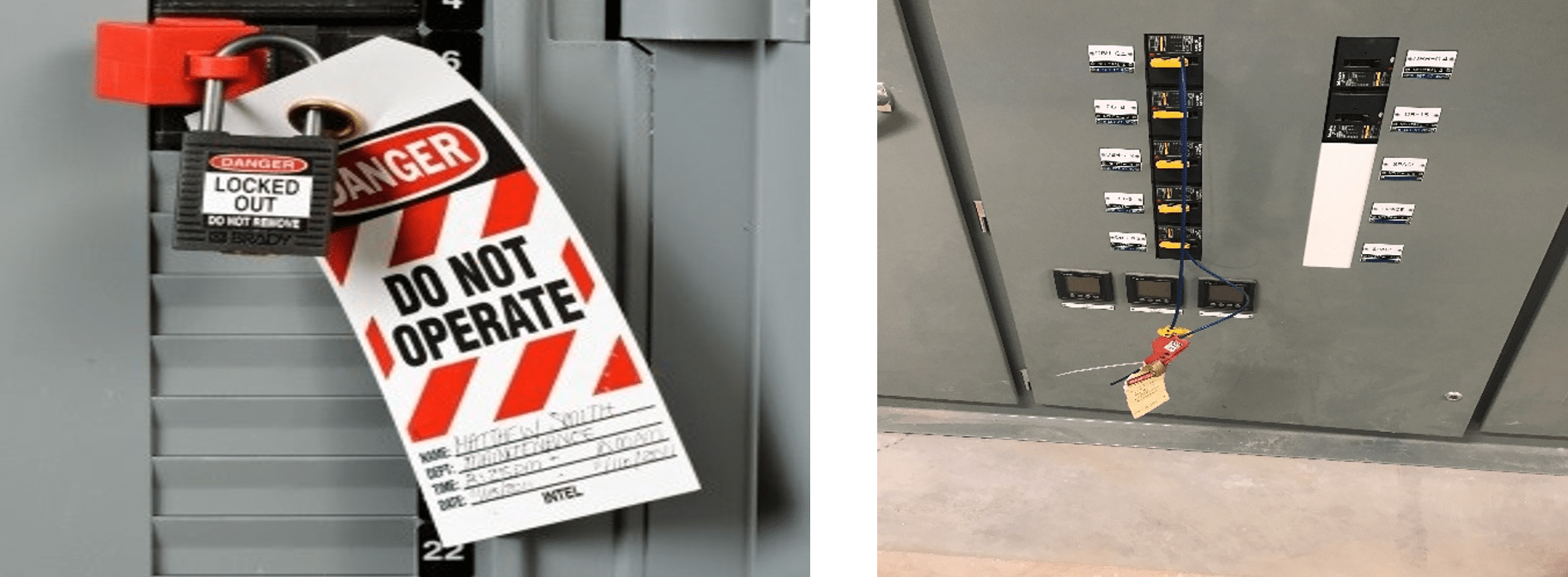

Circuit breaker isolations are locked with a propriety locking device including a padlock or cable lock and electrical tag.

SHAPE switchboard signage is posted on the switchboard door or escutcheon panel when isolations or other work activities are taking place on the switchboard.

When circuit “tails” are removed from the switchboard, an electrical tag or label is assigned to each breaker identifying that tails have been removed. This may also be achieved where the majority of tails are removed via an updated circuit legend or other method of labelling.

Where live cables or other electrical hazards are present, Restricted Space signage is posted at regular intervals at the location of the hazard to ensure high visibility. These locations are marked up on a drawing and form part of the Electrical Survey and the Site Induction.

NB Restricted Access signage placed on a partition wall to reflect a ceiling hazard is not appropriate.

SHAPE Red warning tape – “DANGER – Live Electrical Cables – Do Not Cut” is placed at 2m intervals to all existing cables that are remaining LIVE.

Always consider locations outside of the site envelope such as building core areas, lobbies, toilet facilities, that may need to be accessed for service runs to risers and plant rooms, etc.

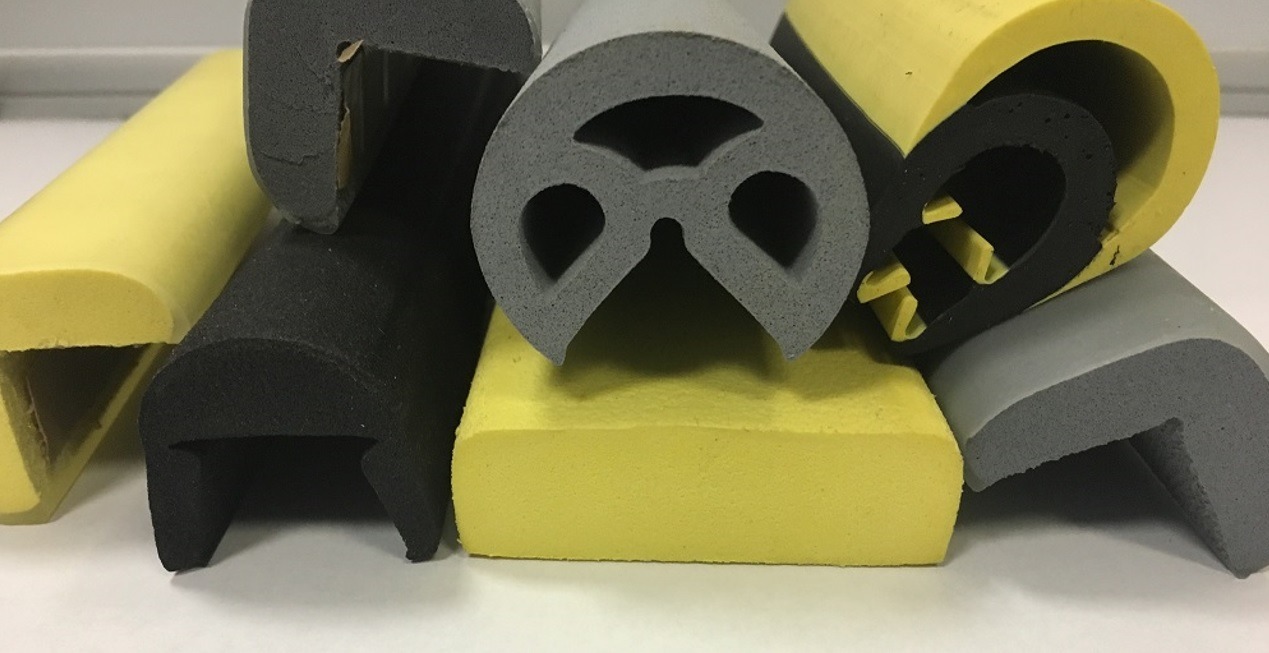

If work must be performed within 1 metre of LIVE Low Voltage (LV) cables (≥50 V AC to 1000 V AC, or 120 V DC to 1500V DC), and these LV cables cannot be isolated, relocated or RCD protected, then the cables must be managed as follows:

- Physical protection suitable for the type of damage that may occur must be installed around the cable in the vicinity of the risk (i.e. the immediate area where the work is being carried out and extending to at least one meter outside the work zone);

- The cable and conduit must be labelled with Red “Live Electrical Cable – Do Not Cut” tape at a maximum spacing of 2.0m;

- Ceiling signage must be installed to alert workers of the potential risk in the work area.

External work areas are assessed for overhead and underground services hazards. Hazards and controls are detailed within the Electrical Survey and associated contractor SWMS.

Use of Plant and Equipment in proximity of overhead or underground power has been risk assessed and controls implemented (e.g. exclusion zones, spotters, supply authority permits).

When work is to be performed in proximity of live electrical apparatus (at a defined safe approach distance and in accordance with the supply authority permits), a risk assessment will be undertaken and safe systems of work developed (including emergency response procedures) in consultation with the workers involved, the site electrician and when required the energy authority or provider.

Workers involved with work in proximity of live electrical apparatus will need to provide evidence of competency in UETDREL006 – Work safely in the vicinity of live electrical apparatus as a non-electrical worker, or an equivalent / superseded competency unit such as UETTDREL14, UETTDREL14A, UETTDREL04B, UETTDREL04A.

Note: Work in proximity of live electrical services may include activities such as telecommunications, vegetation control, scaffolding, rigging, lifting operations, painting or any other activity that requires working safely and complying with requirements, established procedures or safe systems of work near live electrical apparatus by a non-electrical worker.

Ongoing review of electrical hazards and controls takes place via site walks, Procore Hazard Observations, Procore Site Inspections and Task Inspections.

New or increased electrical hazards are risk assessed and any changed conditions communicated via Toolbox Talk. Changes to electrical safety controls are reflected in an updated Site Induction.

Prior to energising new circuits the licensed electrician performs testing in accordance with the Testing, Energising and Commissioning Plan. Test results are provided by the licensed electrician prior to and after energising. Each electrical services trade completes a separate Testing, Energising and Commissioning Plan prior to energising their installation, e.g. fire services, mechanical, security electricians, etc.

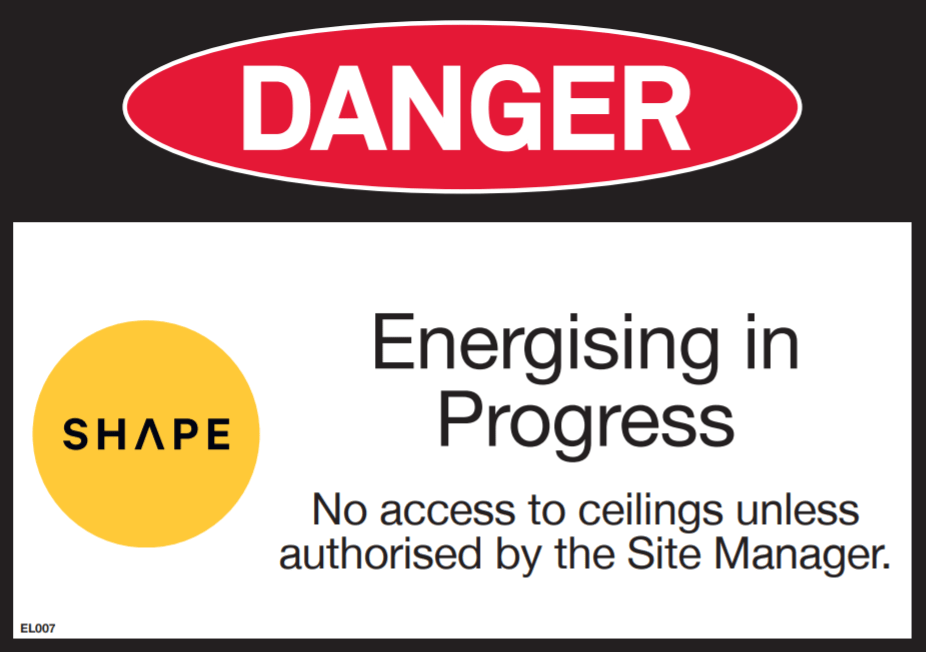

Prior to energising, Energising in Progress warning signage is installed at regular intervals throughout the site and at the site entry point.

Prior to energising, all workers have participated in the Record of Toolbox Talk – Electrical Energising to communicate electrical hazards and changed site conditions in relation to energising activities. This may include changes to temporary power and lighting.

Once energising has commenced, no trades other than electricians are allowed in the energised ceiling space without a documented risk assessment completed for the area that needs to be accessed, and the controls identified in the risk assessment have been put in place.

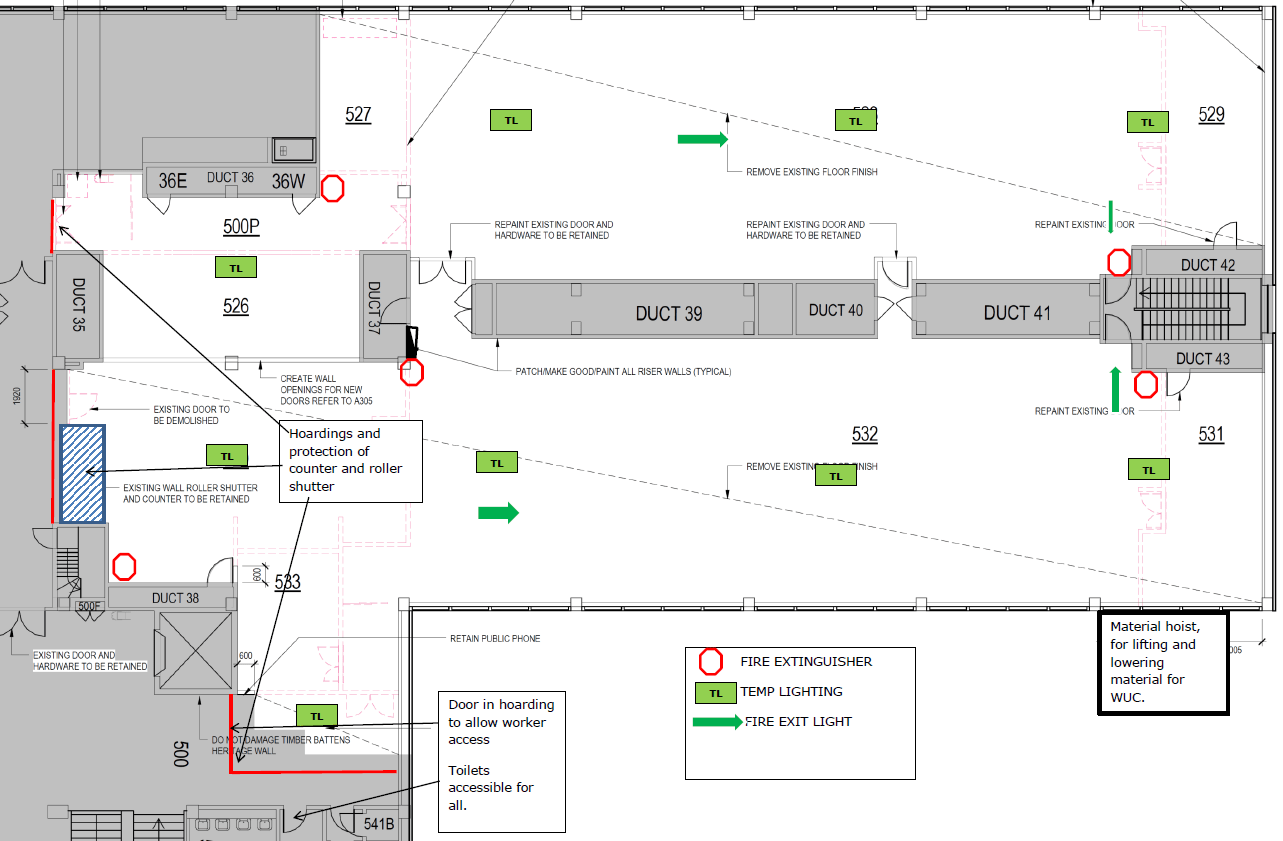

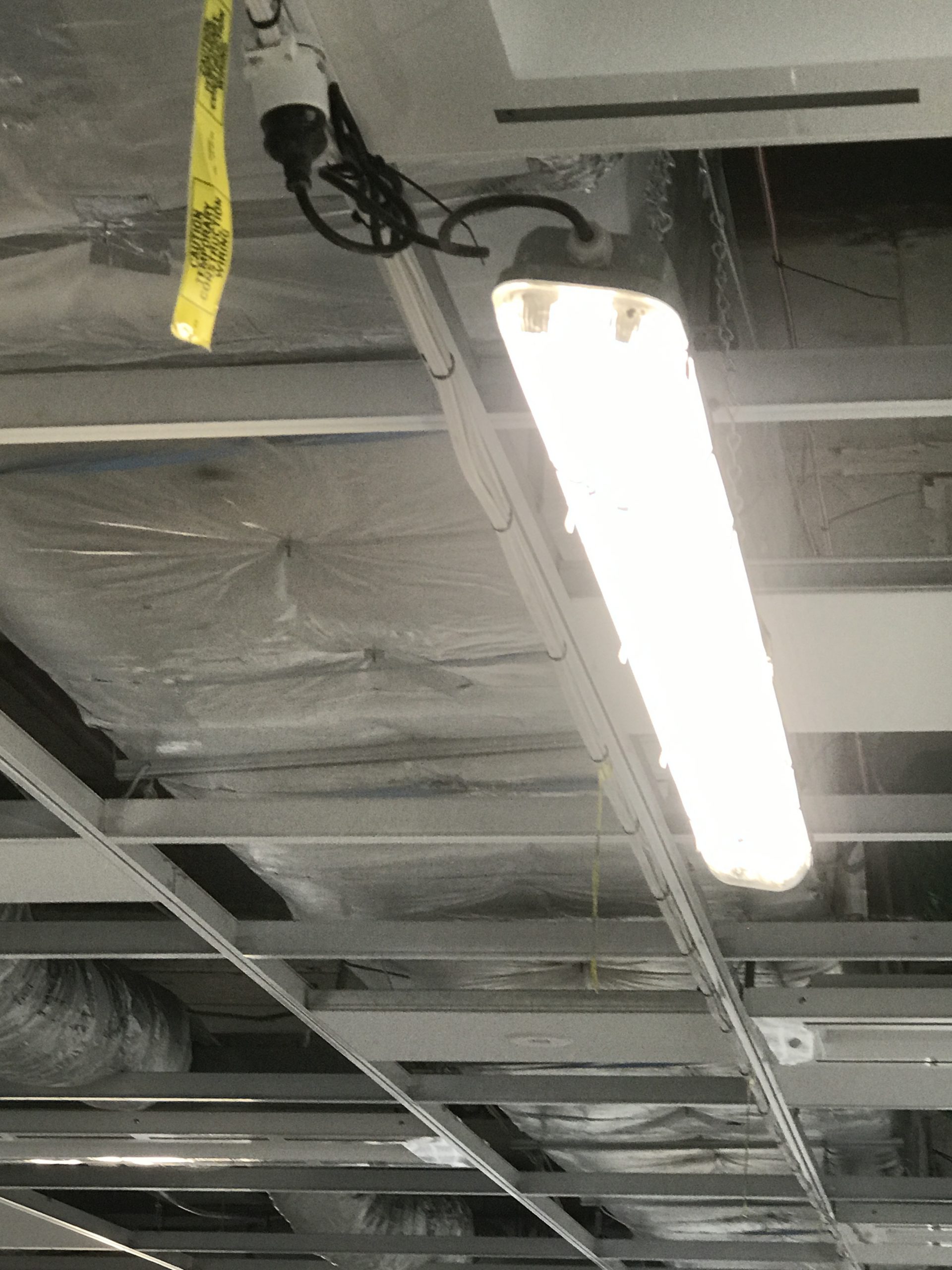

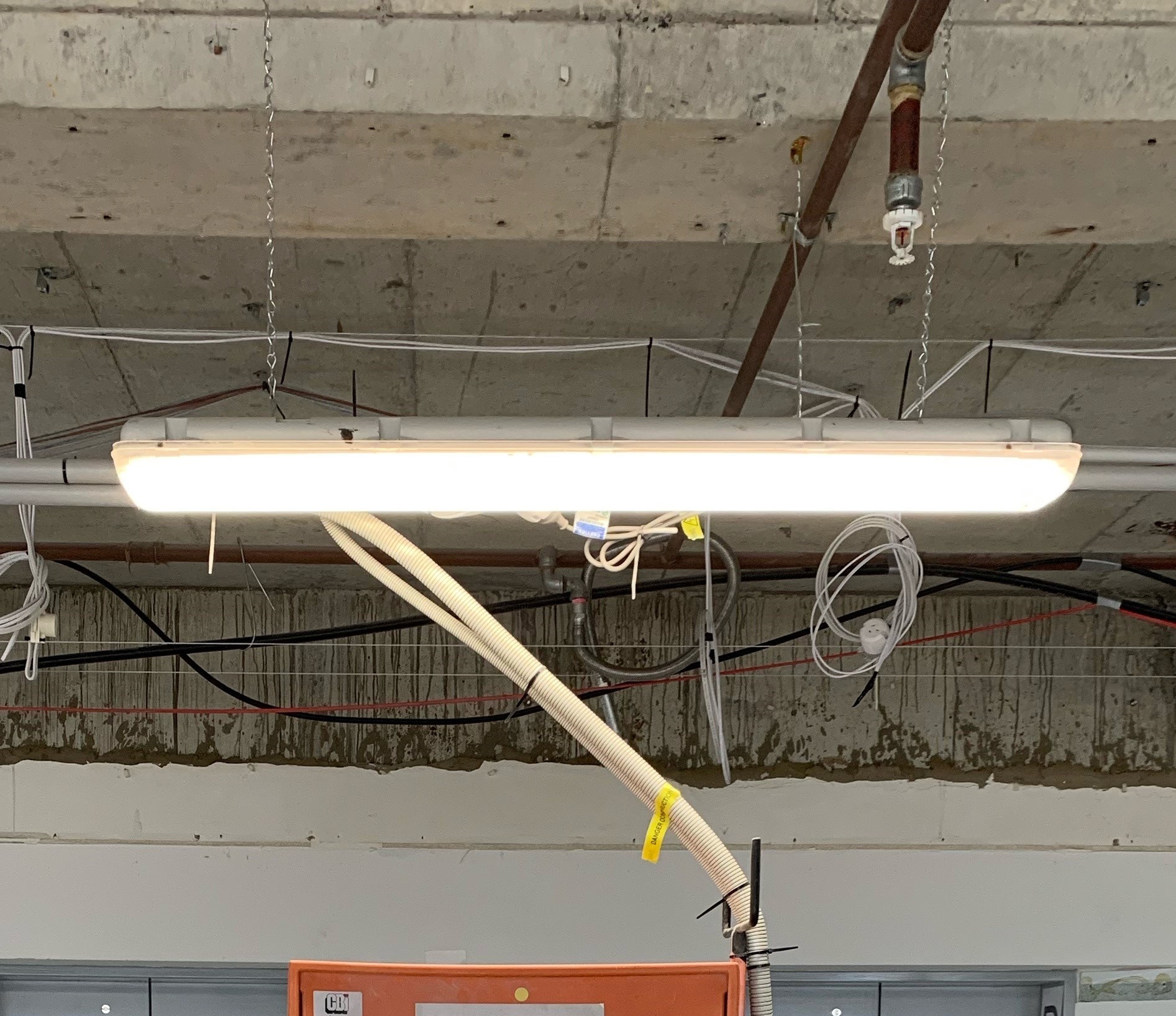

Construction lighting supplied via temporary construction switchboards is the preferred method of site lighting for SHAPE projects – refer to the SHAPE Electrical Safety Procedure. This SMS is to be reviewed in conjunction with the Temporary Switchboards SMS and Construction Wiring and Cord Extension Sets SMS.

Prior to commencing the installation of construction lighting, the project team reviews the project documentation and plans for the location of construction light fittings to ensure adequate lighting levels will be maintained as the project progresses.

NB – the reliance on task lighting for later stages of the project as partitions close up is not preferred.

Construction lighting is fitted below ceiling levels, allowing lighting to be maintained throughout the life of the project without impacting lighting levels when the ceiling is closed.

Construction lighting to areas with finishes such as wall and floor tiles is extremely important to ensure a high quality finish and will usually require a lux level that replicates the final lighting levels.

Lamps / globes in light fittings are protected against mechanical damage, i.e. wire cages or anti vandal style diffusers.

All light fittings are suspended from jack chains or fixed to stable building elements.

Office light fittings are not used as temporary construction lighting as they do not comply with the Australian Standard for construction lighting.

Where more than one lighting circuit is installed, the lighting circuits are distributed between RCDs.

Adequate lighting is provided to all work areas and other locations including stairways, fire exits, passageways and adjacent to switchboards to allow safe access and egress.

Exit lighting with battery back-up (or self-illuminating exit signage) is posted so that it is visible from all locations on site.

NB the project floor plan / partition layout must be considered when planning the position of emergency exit lighting and signage to ensure adequate lighting is available as the project progresses.

Emergency lighting with battery back-up is installed at least every fourth light, above temporary switchboards and within 2 metres of exit signs.

Other types of lighting:

Portable luminaries / task lights (e.g. flood light tripods) have protection / mechanical guard to the lamp and adequate stability, or are secured to a suitable structural element.

Task lighting is the least preferred option for site lighting.

Existing light fittings may be used for lighting in certain circumstances such as minor works activities if supplied via an RCD protected circuit. Refer to the Electrical Safety Procedure for the definition of minor works where this may be permitted.

Existing light fittings may not be used if they have been removed from the ceiling grid.

This SMS is to be reviewed in conjunction with the Temporary Switchboards SHAPE Minimum Standard, Construction Lighting SHAPE Minimum Standard and Electrical Safety Procedure.

Construction wiring is segregated from permanent / existing wiring.

Construction wiring is not fixed to free standing fences that have no fixed posts (or equivalent means of support).

NB this may include certain types of hoarding and other temporary structures.

Construction wiring is supported by dedicated catenary wires, cable clips or cable tray – the use of existing metal services, hangers, ceiling framing, etc. is not permitted.

Construction wiring is physically protected where there is a risk of mechanical damage – using medium duty, heavy duty or corrugated conduit, armoured cable, or flexible electrical hose – unless the risk assessment shows such protection is not necessary to maintain electrical safety.

Construction wiring is marked with iridescent yellow tape with the words ‘construction wiring’ spaced at intervals not exceeding 4 metres.

NB – the use of SHAPE Red warning tape is not permitted on construction wiring.

Construction wiring is positioned to avoid crossing roadways or access ways where cranes, high loads or heavy machinery may travel. If this is not possible, an effective means to minimise the risk of vehicular contact with the overhead wiring system is provided and detailed within the Electrical Survey.

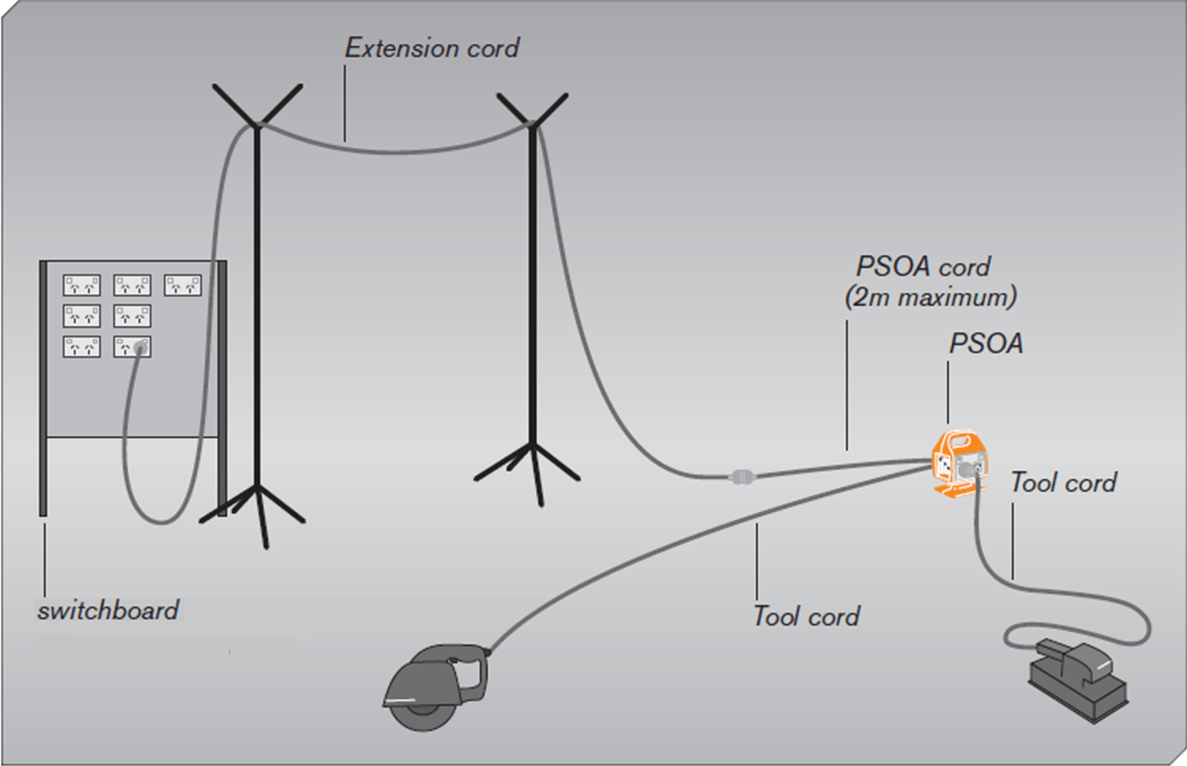

Leads are only used when supplied by a temporary construction switchboard on the same level. If this is not achievable, a documented risk assessment must be undertaken.

Switchboards are supplied by a new run of cable which has a minimum cross sectional area of 4mm2.

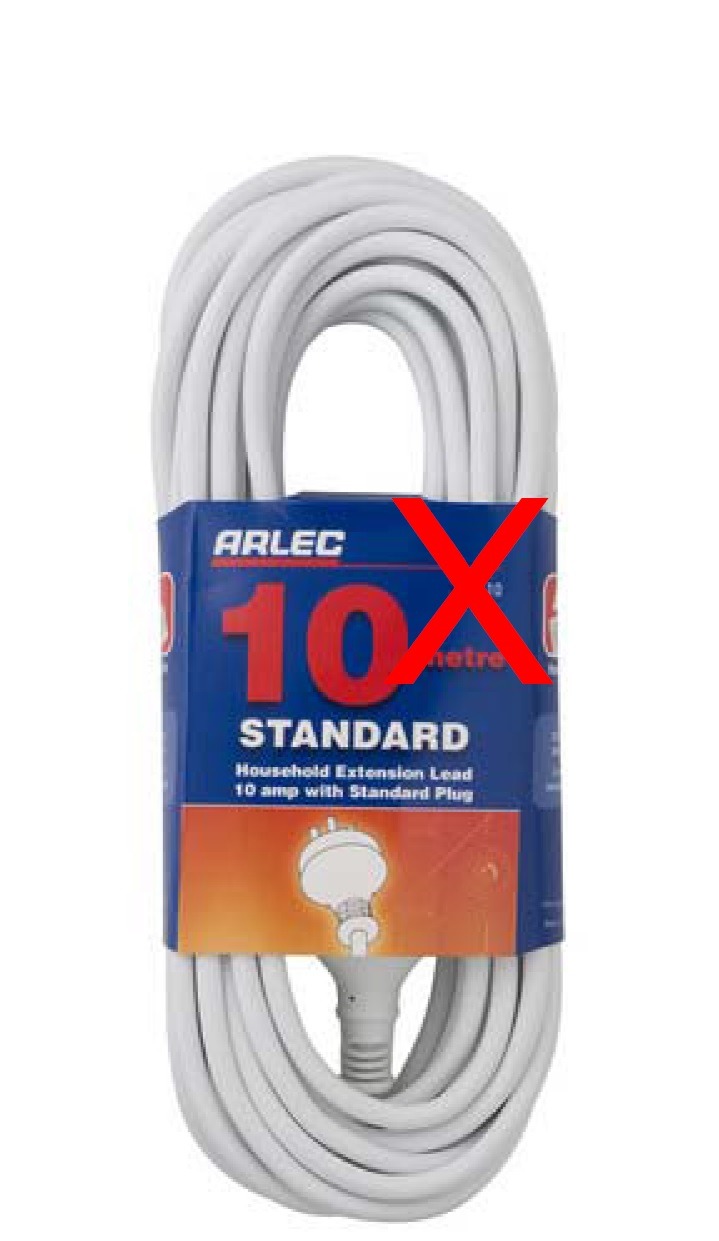

Flexible cords, cord extension sets, flexible cables and accessories:

Flexible extension cords have heavy duty sheathing.

Domestic type flexible cord extensions are not used.

As a general rule, 10A cord extension sets with a cross-sectional area of 1.5mm2 should not be longer than 20m. If the supply cord of the tool is greater than 2m, then this must be included when calculating the maximum length of 20m.

Extension leads are supported on insulated hooks or lead stands.

Cord extension sets emanating from the temporary construction switchboard are wrapped around the insulated tie bar, and then supported on an insulated support directly above the switchboard at a minimum of 2.2m above the floor level.

Cord extension sets are not in contact with any conductive building materials or heat generating equipment (e.g. ceiling grid, temporary construction lighting, scaffolding, sprinklers, etc).

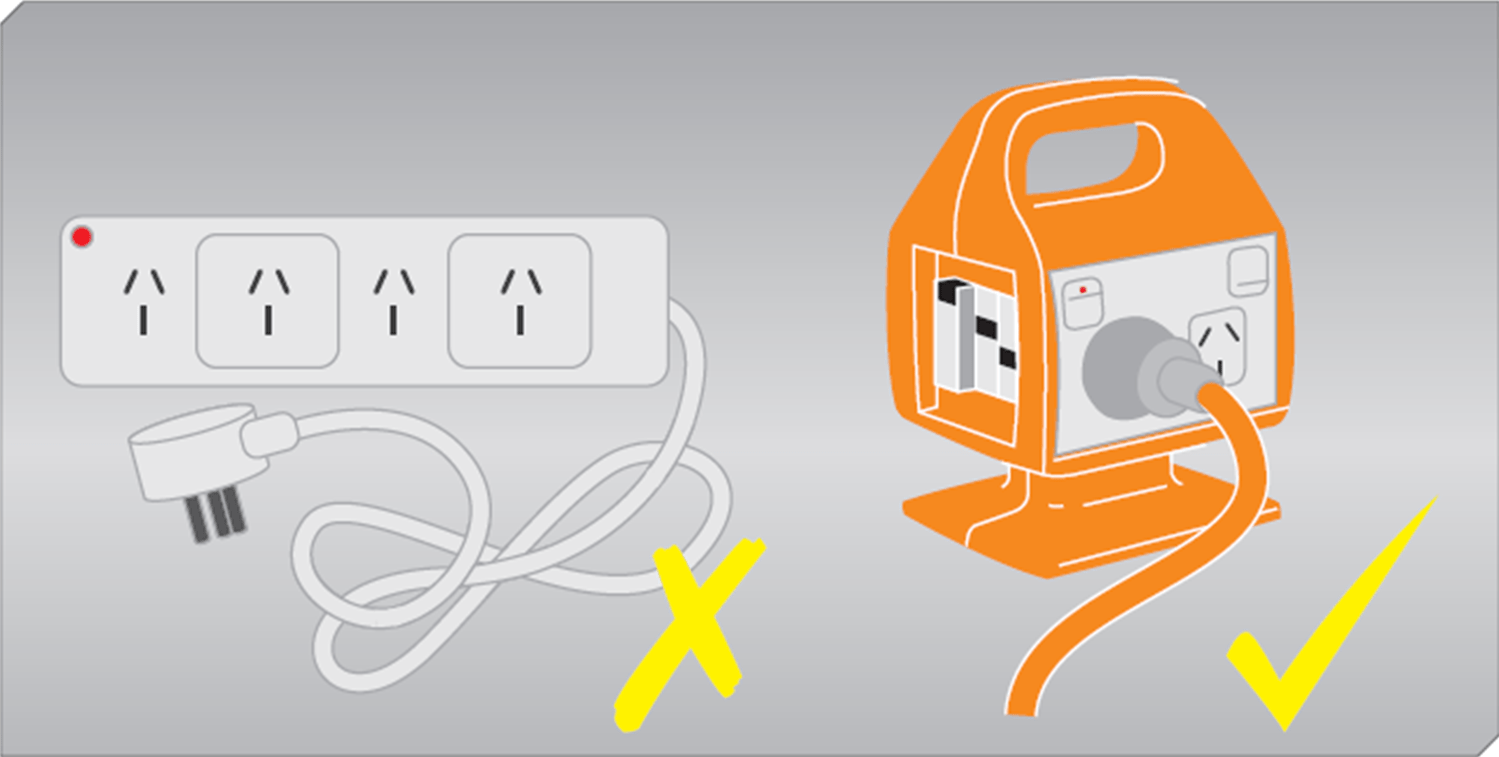

Portable RCD boxes (Portable Socket Outlet Assemblies or PSOAs) are RCD protected and meet the requirements of AS 3012.

Portable Socket Outlet Assemblies (PSOAs) and cord extension sets display a current test tag. New in-service tools and equipment are also tagged.

Existing power supplies should only be used for minor or short duration works (e.g. 2-3 days and do not have any demolition or building works).

This can be achieved via:

- RCD located at the existing switchboard supplying the final subcircuit, OR

- A Portable Socket Outlet Assembly (PSOA) plugged directly into the socket outlet.

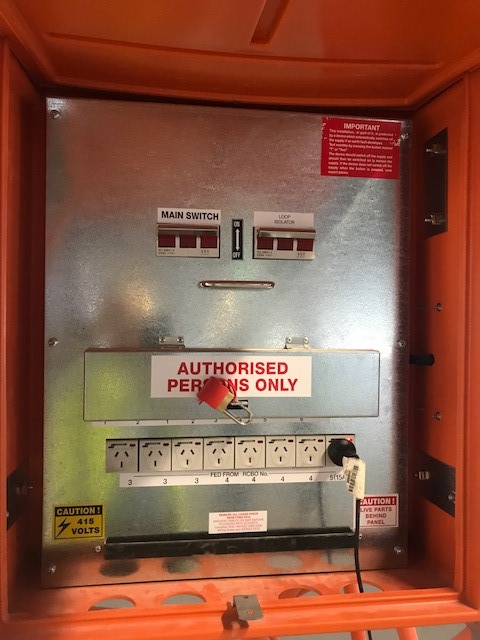

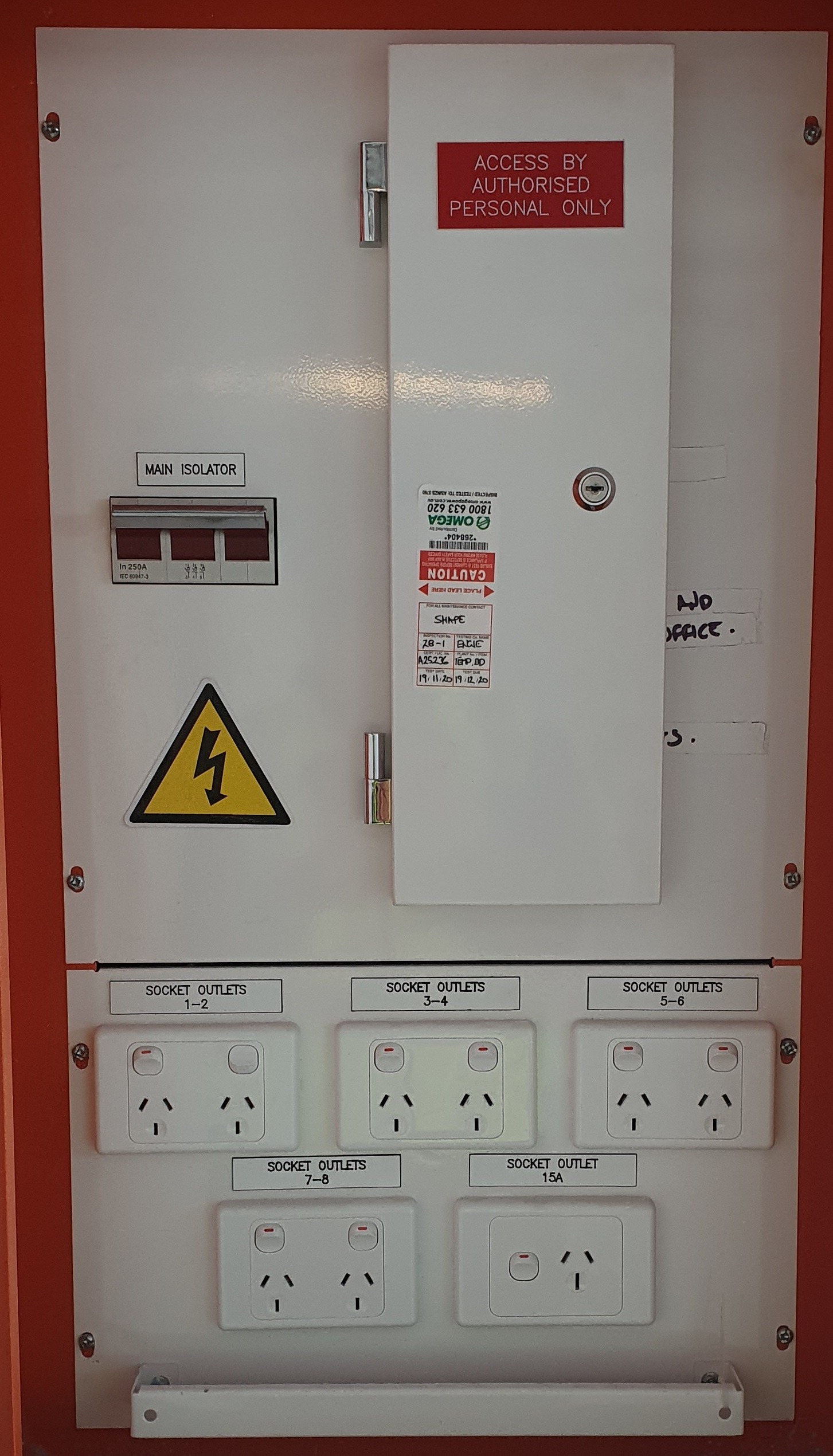

The use of Temporary Switchboards is the preferred method of power supply for SHAPE projects – refer to the SHAPE Electrical Safety Procedure. This SMS is to be reviewed in conjunction with the Construction Lighting SMS, and the Construction Wiring and Cord Extension Sets SMS.

During pre-construction, the project team reviews the scope of works with respect to power and lighting supply requirements, for inclusion into the Project Risk Register and Project Delivery Plan.

As part of the site-specific Electrical Survey the required number and locations of temporary switchboards for the project is determined.

Switchboards are located / positioned to suit the maximum flexible cord lengths – generally no more than 20 metres.

Power supply for trade requirements has been considered including mixing areas, battery stations and 3 phase power for equipment such as floor grinders.

Domestic switchboards are not used. All switchboards fully comply with AS/NZ 3012 Electrical installations – Construction and demolition sites, and are installed in accordance with AS/NZS 3000 Wiring Rules.

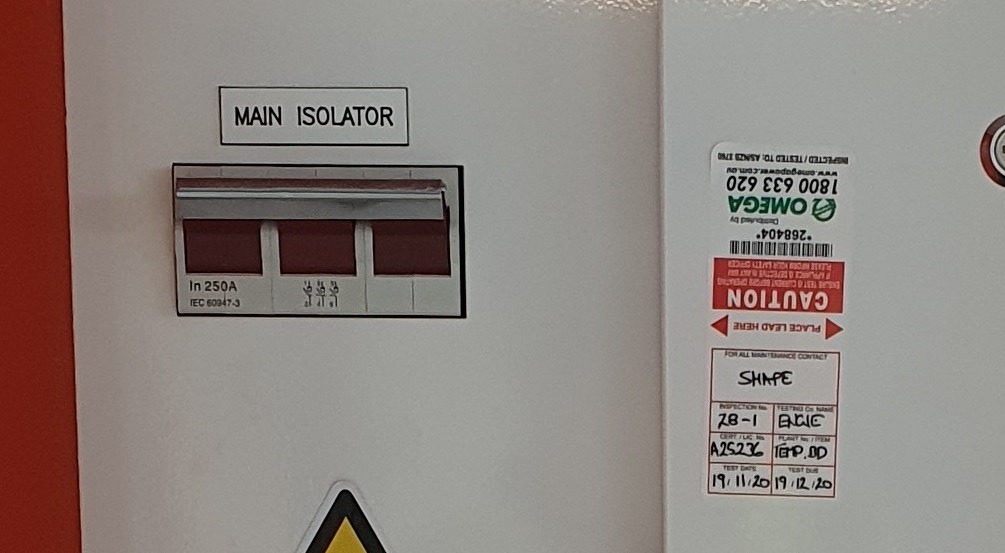

After their initial installation, all switchboards are verified (inspected and tested) in accordance with AS/NZS 3000 and AS/NZS 3017. The testing equipment used, serial number and calibration date/certificate are documented with the test records, which have been provided to SHAPE prior to use. Re-testing is completed every three months.

The SHAPE Site Manager uses the Electrical Survey or this Temporary Switchboards SHAPE Minimum Standard to check all switchboards prior to their use on site, and regularly thereafter.

Final sub-circuits are protected against overload and short circuit by a circuit breaker RCD protection with a maximum rated residual current of 30 mA, which operates in both the active and neutral conductors. Lighting circuits are distributed between RCDs to minimise the impact of the operation of a single RCD.

Switchboard RCDs undergo calibration testing every 3 months (every 1 month in Victoria). Test results are provided to the SHAPE Site Manager.

Push-button RCD tests (by users) are performed at least once per day prior the use of portable RCD equipment.

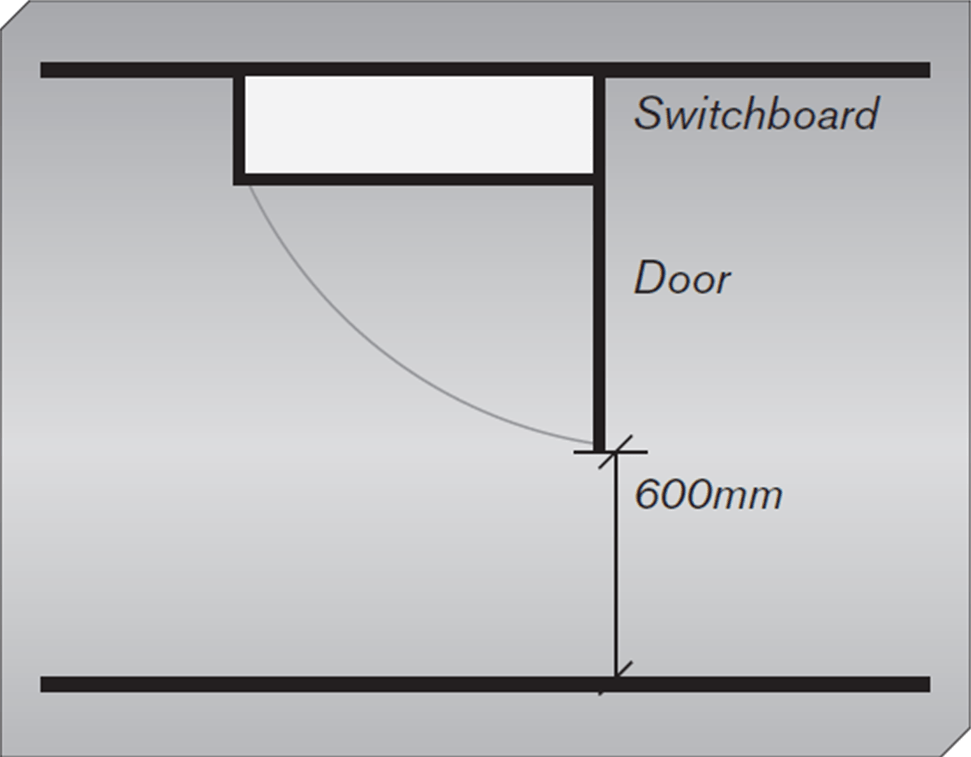

Switchboards are readily accessible and clear from obstructions. A minimum clearance of 600mm is maintained to allow unimpeded opening of the switchboard door.

Switchboards are of robust construction and materials, to withstand mechanical damage from the environment or other external influences that may be expected at the location. In order of preference, this may include:

• Attachment to a wall, pole, post, floor or other stable structure

• Attachment to a freestanding or temporary structure, in an elevated position suitably designed for the purpose. It must be stable and the design must take into account any external forces that may be exerted on the board (e.g. bolted to the slab, fixed securely to the ground, or secured to a wide base of support)

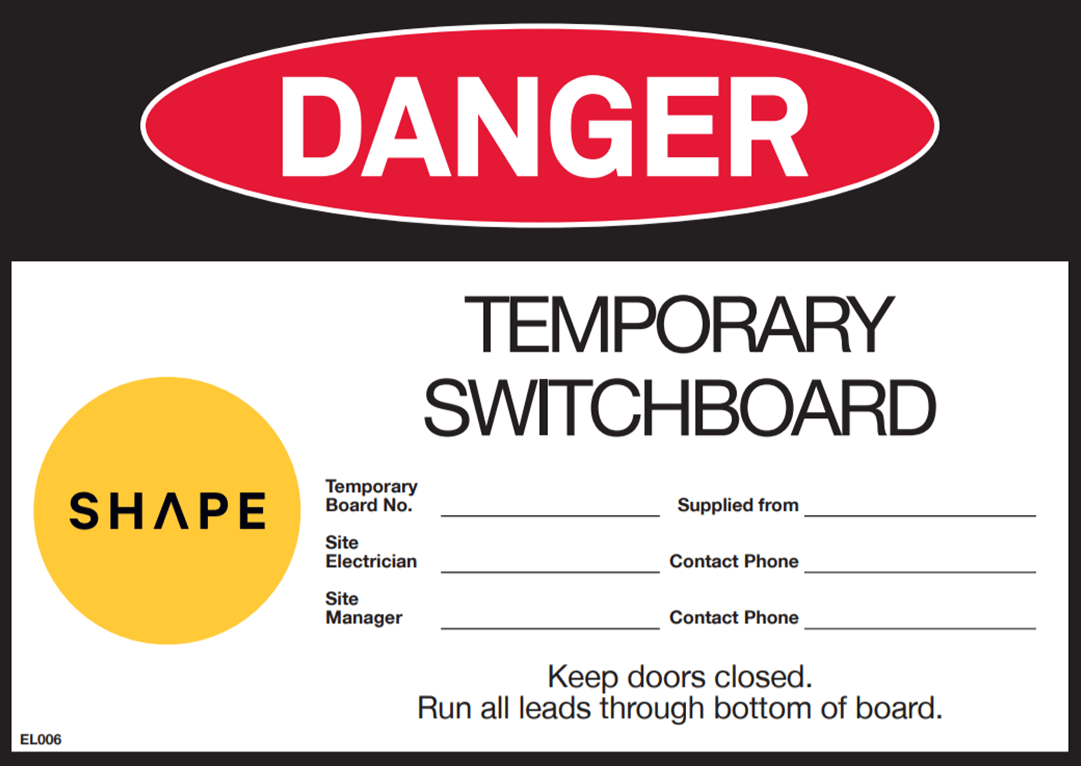

The SHAPE temporary switchboard signage is posted on the front door of all switchboards. This is to ensure that each switchboard identifies the source of supply from which it originates, and that each switchboard is marked by way of numbers, letters, or both to distinguish one switchboard from another.

In multi-level buildings, switchboards are positioned in a manner that eliminates the need for flexible cords or cables to be run between levels (exceptions for work in lift shafts, stairwells, service shafts, formwork, external staging or sub-mains of construction wiring).

For outdoor locations and areas susceptible to moisture, switchboard enclosures have a minimum degree of protection of International Protection (IP) rating 23.

Live parts are effectively protected at all times against contact by people operating equipment on the switchboard, including the connection or disconnection of plugs to socket outlets (i.e. escutcheon panels are secured and all pole fillers are in place).

An insulated tie-bar or similar arrangement is in place on each switchboard for the anchorage of cables or flexible cords, in order to prevent strain and mechanical damage at their connections or terminations.

An insulated lead support is provided directly above the board, at a minimum of 2.2m above the floor level.

Each switchboard has a door or lid to maintain a degree of protection. The door or lid:

• Requires the use of a tool for removal

• Is fitted with a facility for locking

• Is fitted with a means of retaining the door in the open position, when the board is in use

• Is kept closed except when access is required

• Allows the safe entry of leads away from pinching points in the door, to prevent damage to the leads

• Has words to the effect of “Keep Doors Closed. Run all leads through bottom of board.”

The “live parts” or “electric shock” symbol is displayed in locations where additional attention is required to be given to the removal of covers and the like (i.e. as a minimum on the escutcheon panel).

All switchboards are provided with a clearly labelled main isolating switch, which interrupts supply to all final subcircuits, submains and socket outlets originating from the board.

When the isolating switch has been activated, provision must be made to prevent electrical equipment from being inadvertently energised, i.e. deliberate action in addition to the normal method of operation is required to energise the circuit. This provision may be via the locking of the switchboard door, or another lockable space or enclosure. Warning tags or notices alone are not acceptable. Short-circuiting and earthing may only be used in addition to locking.

Lockable covers are fitted over RCDs associated with outgoing circuits. These covers must not prevent access to the isolating switches. This is not a mandatory legal requirement in all states however SHAPE adopts this well known practice as a national minimum standard.

All cable entry ports are insulated to protect cables from damage.

A person has been nominated to ensure that all power circuits are isolated or made inaccessible so as to eliminate the risk of fire, electric shock or other injury to persons after completion of the daily work.

All temporary supply mains are protected by a circuit breaker or high rupturing capacity (HRC) fuses.

Switchboards display only current testing information, i.e. all out of date test labels have been removed.

Switchboards are supplied via new cable runs.

Note: this means that existing cables may not be used to supply temporary switchboards or lighting.

Submains cables supplying temporary switchboards are physically protected in conduit from the board and into the ceiling space or beyond if the works activities in the location present a risk of damaging the cable.

Battery charging tables have been provided to the side of, or behind switchboards.

Auxillary socket-outlet panels meet the requirements of AS/NZS 3012 Section 2.6.11. Of note, they must be:

• Located at a height of between 1.2 and 2m above the floor

• Securely mounted to a permanent structure or a temporary structure that has been specifically designed for the purpose

• Must be individually controlled by a double pole switch

Portable RCD boxes (Portable Socket-Outlet Assemblies or PSOAs) must meet the requirements of AS/NZS 3012 Section 2.6.10. Of note, they must:

• incorporate over-current and RCD protection

• be of robust construction

• have extended sides or covers over the outlets

• have a degree of protection appropriate for the environment (IP33 as a minimum)

• incorporate a heavy duty flexible cord no more than two metres long

Domestic type powerboards, double adaptors, three pin plug (piggy back) adaptors and homemade powerboards must not be used on construction or demolition sites.

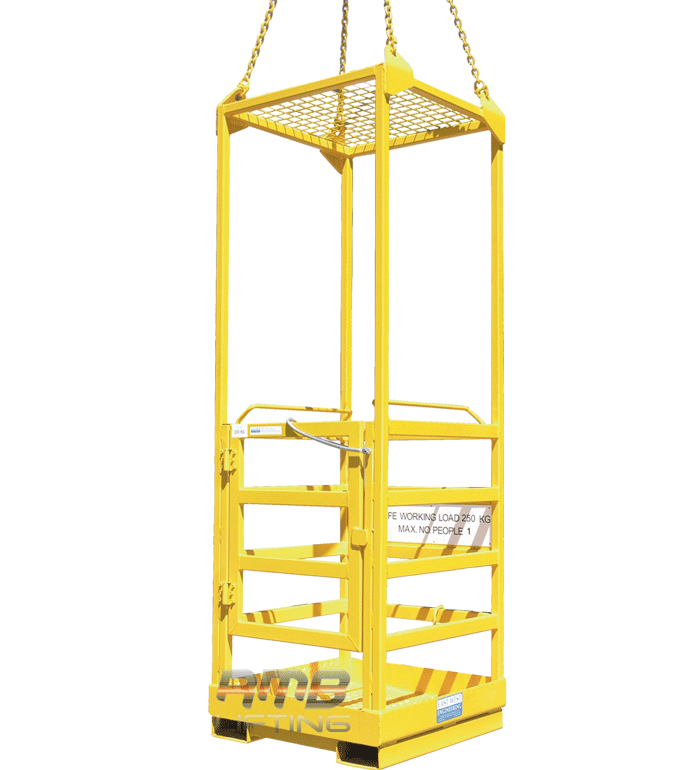

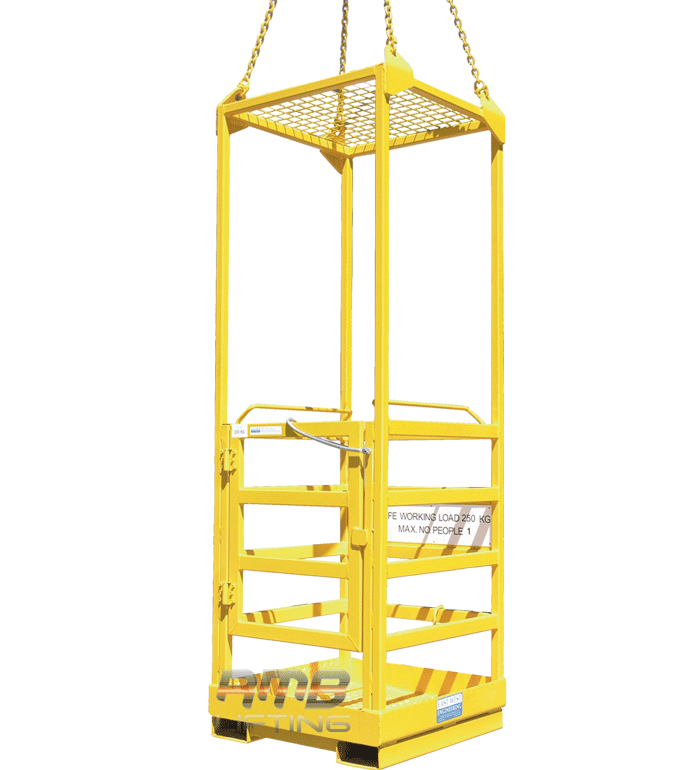

EWPs are mobile platforms that lift or lower people or equipment from a base support using either a hinged, articulated or combination (hinged and articulated) device. Types of EWPs include scissor lifts, self-propelled boom lifts, trailer or vehicle mounted lifts and telehandlers with elevating work platform attachments. Construction work using EWPs is high risk construction work.

During preconstruction, the project team reviews the scope of works with respect to Elevating Work Platforms for inclusion into the Project Risk Register and Project Delivery Plan.

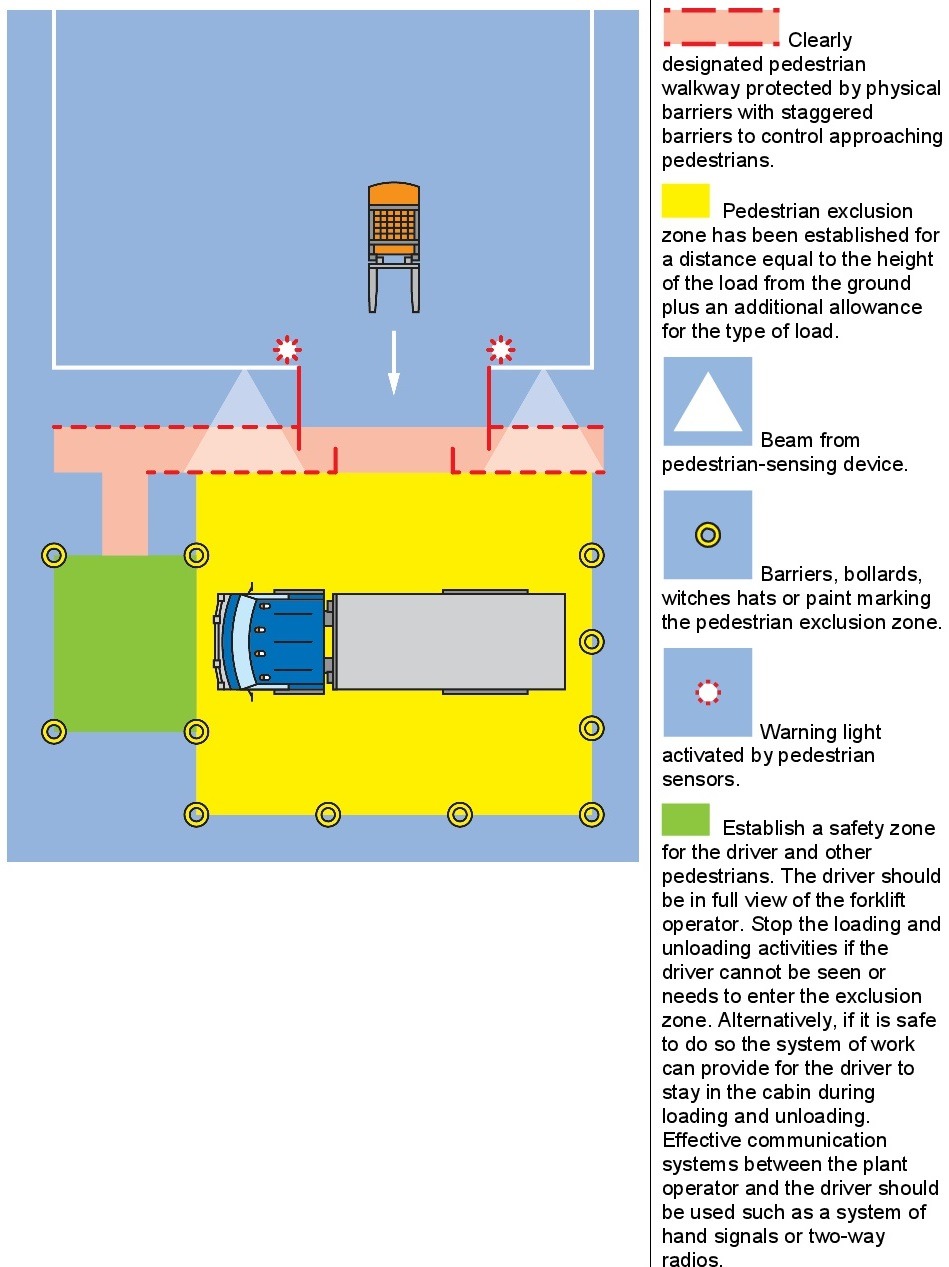

The site’s designated loading / unloading area has been assessed for overhead services, weather conditions, lighting, traffic routes (both internal and external to site), eliminating the risk of collision with other people or plant, and the ground has been assessed by a structural engineer or geotechnical engineer (when required) to ensure it is adequate to support the EWP and its transport vehicle

Contractor Safe Work Method Statements (SWMS) are prepared by subcontractors for construction work associated with EWPs, and reviewed using the SWMS Review.

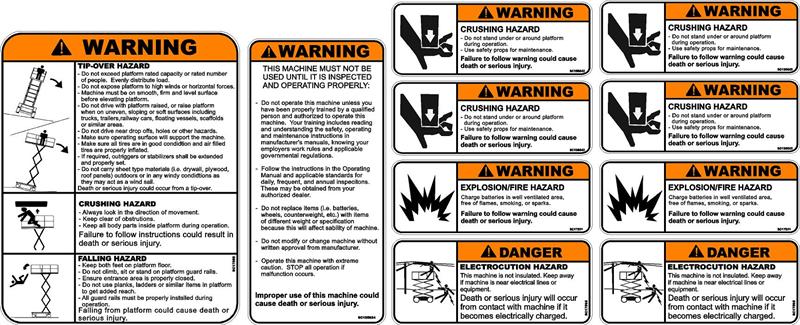

The selected EWP is the most appropriate plant or equipment to perform the work task, and the SWMS or methodology elaborate on appropriate hazards and controls for the work, including but not limited to:

- structural failure, overturning, or collapse of the machine

- contact or collision of the EWP with people, plant and structures leading to crush injuries and entrapment

- inadequate ventilation in the area the EWP is used

- restricted working space, and

- falling objects and falls from heights.

Alternative access methods, such as scaffolding, have been considered to reach and carry out the task prior to the decision to use an EWP

The contractor’s site-specific SWMS or methodology considers the hazards and controls regarding the delivery and collection of EWPs, i.e.:

- Transport operators are trained and competent in how to operate the EWP, how to use the loading equipment and load restraining equipment, how to inspect load restraining equipment prior to use, emergency procedures for the type of plant, etc.

The site’s designated loading / unloading area is then prepared prior to the estimated arrival time of the EWP, including but not limited to traffic control, spotters and warning signage in accordance with the site Traffic Management Diagram

A Plant and Equipment Induction has been completed. Where required, the following documentation is reviewed and copies are maintained on site:

- The plant provider’s risk assessment

- The contractor’s SWMS related to the use of the plant, which includes site specific requirements

- Daily inspection logbooks

- Service records

- Operations manual

- Verification of operator competency

- Plant and Equipment Registration (in line with state and Territory regulatory authorities – refer to Item 3 of the Plant and Equipment SHAPE Minimum Standard)

- Registration with Road Authorities where the plant itself is to be driven on public roads

- SHAPE’s Plant Induction sticker may be used to easily identify inducted plant and reinspection timeframes

The Plant and Equipment Register is updated to include the EWP and associated records

EWP tires are in good condition with minimal damage. Puncture proof tyres are used where the loss of inflation could cause instability

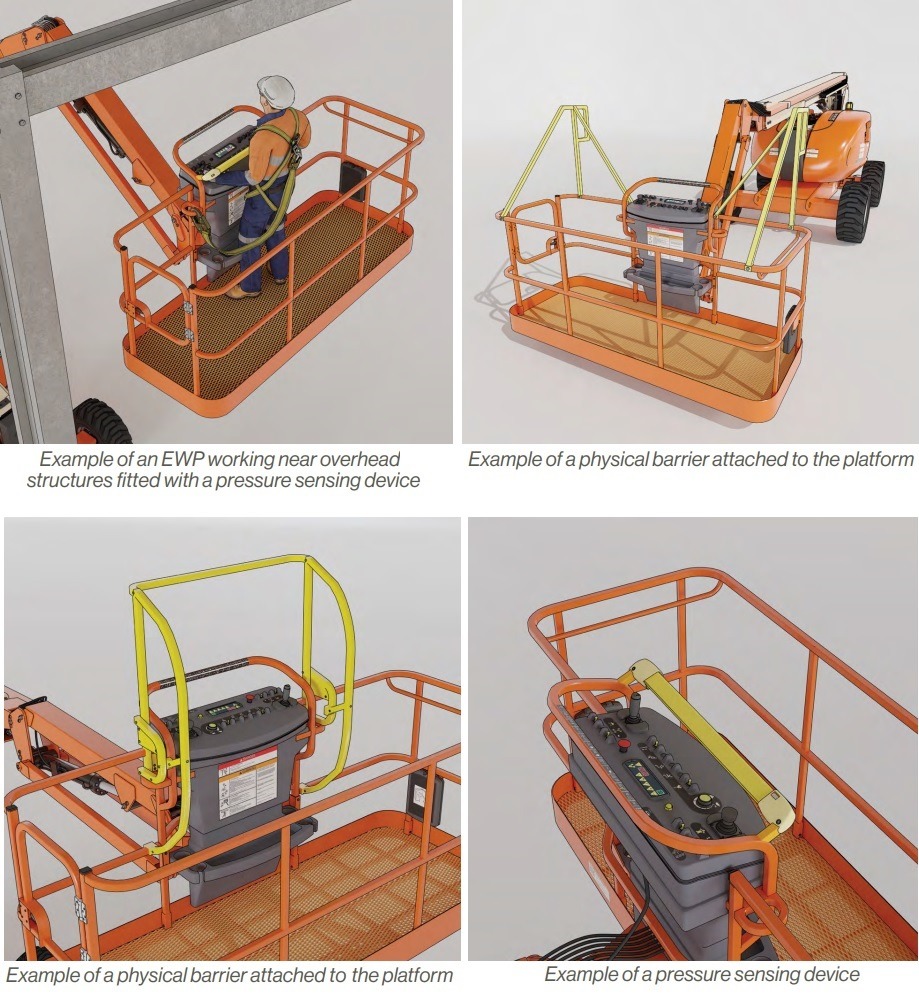

When there is a risk of crush injuries (i.e. when working near overhead structures or services), secondary guarding or protective devices are installed by the manufacturer / supplier.

Such devices may include:

- physical barriers attached to the platform

- pressure sensing devices positioned over the control panel, which detect pending crush incidents and prevent further hazardous movements

- proximity sensing devices which prevent an EWP’s platform from manoeuvring into high-risk areas near to fixed structures

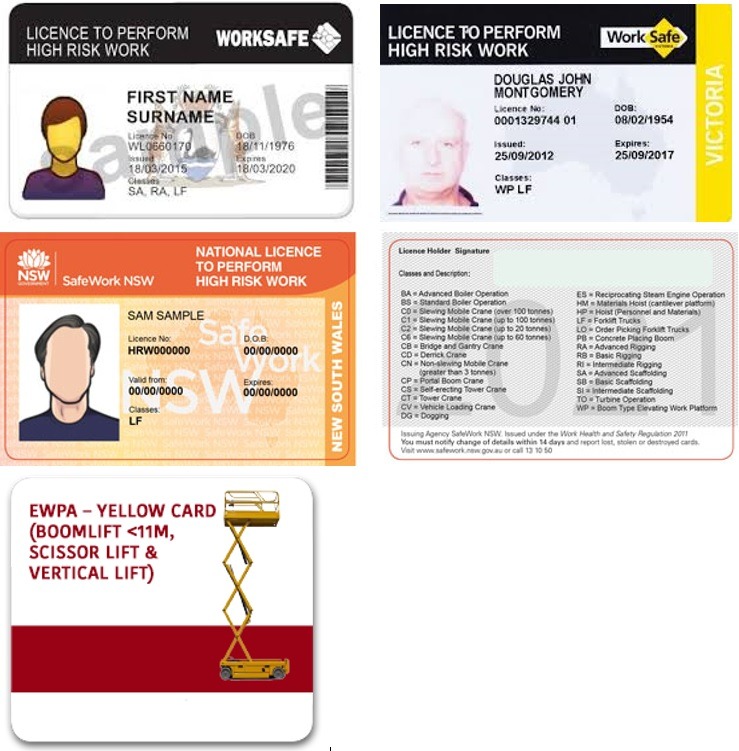

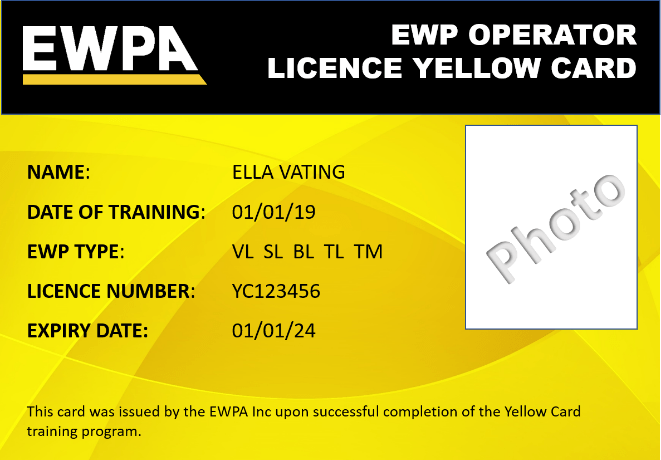

The operator’s competency has been verified in relation to the selected type of EWP, and a photocopy is taken and kept in the site files, i.e.:

- To operate a scissor lift (SL) or vertical lift (VL) of any platform height, there is no requirement to hold a High Risk Work License however operators need to demonstrate that they have been trained in and are familiar with the equipment they are operating. This training can be obtained by undertaking an EWPA Yellow Card course;

- The High Risk Work Licence for boom-type elevating work platforms is not evidence of competency to operate a scissor lift or vertical lift – you must be trained and familiar with scissor lift operation before you can use it;

- To operate a boom-type Elevating Work Platform where the length of the boom is under 11m, evidence of training can also be obtained by undertaking the EWPA Yellow Card course;

- To operate a boom-type Elevating Work Platform where the length of the boom is 11m or more, a High Risk Work License for Boom-type elevating work platforms (code WP) is required

Relevant information, training, and instructions have been provided to workers who are involved in the activity. For example: the Site Induction, Toolbox Talk, training in the SWMS, Pre-Start Meeting.

Overhead and underground services (such as gas, water, fire services, overhead power lines and electrical cables) have been identified through review of As-Builts, Dial-Before-You-Dig and scanning techniques. Relevant asset owners are identified so that they can be consulted in planning for the works

Due to the importance of a prompt rescue, EWP operators should never operate alone in the event they become sick, injured, stranded, suspended or trapped at height due to malfunction or misuse of the EWP.

Support personnel need to maintain line of sight to the operator and should not leave the area until the EWP is lowered to a stowed position and the operator has alighted from the platform.

For scissor lifts less than 11m, as a minimum the EWP Emergency Response Plan is completed by the scissor lift operators and ground-based support / emergency response personnel prior to works commencing.

For all other types of EWPs (i.e. scissor lifts greater than 11m and all boom-type EWPs), in addition to being trained in the EWP Emergency Response Plan the ground support personnel must also:

- be licensed to operate the type of plant they are spotting, with evidence of this competency copied and retained in the site files; OR

- be a trained Dogman / Rigger, with evidence of this competency copied and retained in the site files

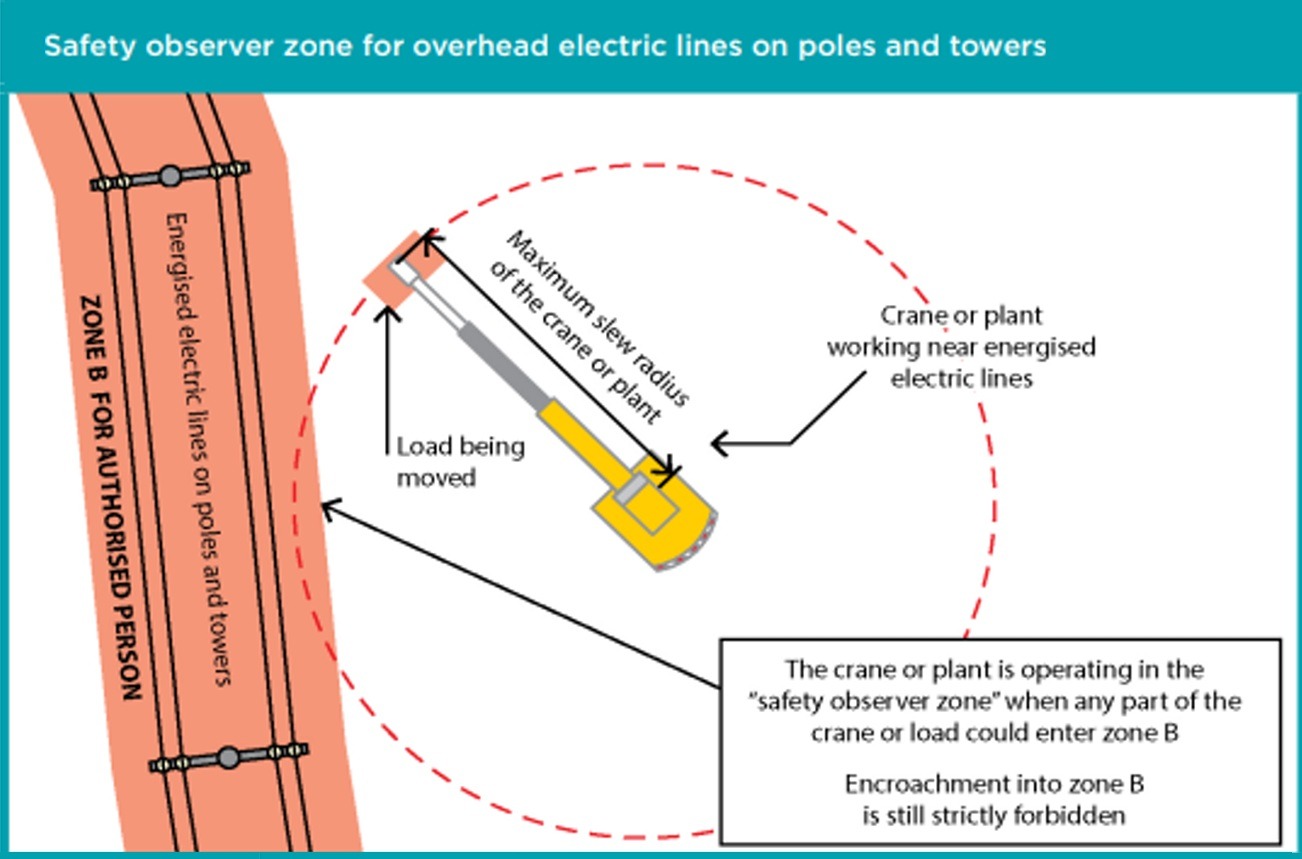

On SHAPE workplaces an EWP should never be used in the vicinity of live overhead electrical lines.

If this situation is ever to occur, a detailed SWMS, Emergency Response Plan (which includes provisions for a trained LV rescue person with an LV rescue kit to monitor the activity), and Electrical Deviation Risk Assessment must be endorsed by the relevant SHAPE state General Manager or delegate prior to works commencing.

One spotter will be required for each item of plant or equipment operating in the vicinity of overhead electrical lines. Spotter competencies must be copied and retained in the site files, and must include:

- The license / competency to operate the type of EWP (or Dogman / Rigger competency)

- A current competency to ‘Provide First Aid’ (HLTAID003) or equivalent

- A current competency to ‘Provide Cardiopulmonary Resuscitation’ (HLTAID001) or equivalent

- (In Victoria only) an approved Spotter training course (22325VIC) (Course in Workplace Spotting for Service Assets) and hold a current Spotters Registration Certificate/Card which is valid for a period of three (3) years

Emergency controls are clearly visible, known by operators and spotters, and are accessible at all times during operation of the EWP

Attachments fitted to EWPs to hold material have been installed as per the manufacturer’s instructions by a competent person (such as a fitter or mechanic) and have been inspected and approved by an engineer or workplace safety regulator

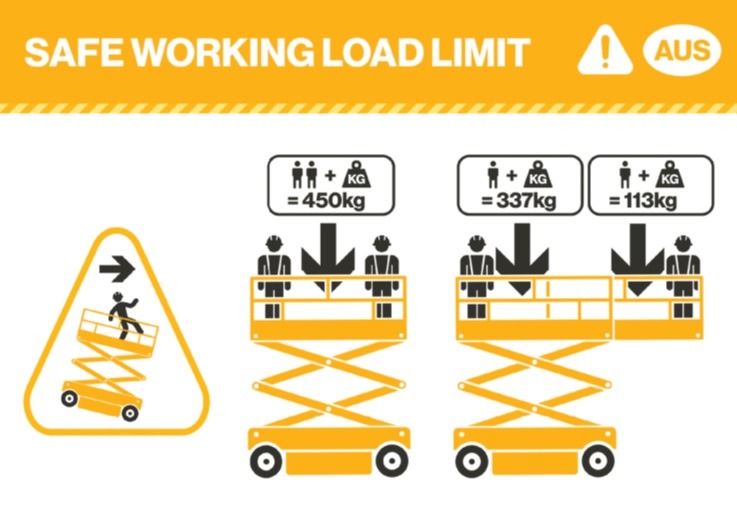

Safe working loads are displayed on the EWP and are understood by the operator and passengers

Permanently fixed and legible operating instructions (decals) are displayed at operating positions, i.e. at the ground controls, or cabin and basket controls

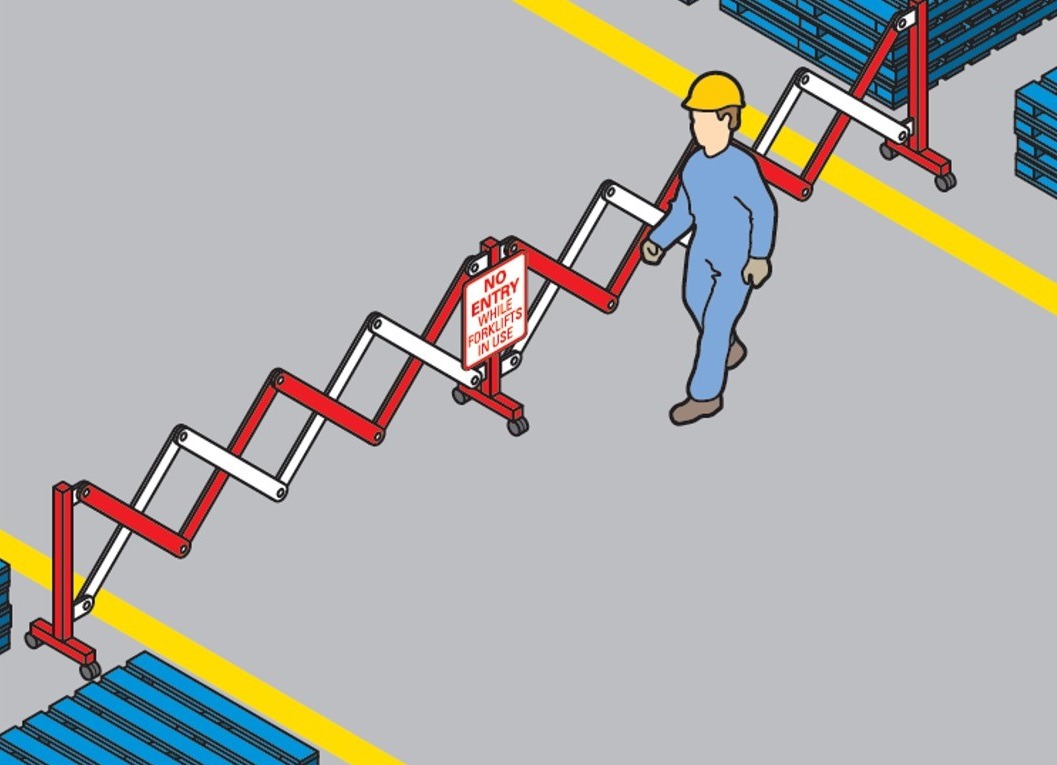

Exclusion zones and warning signage are in place to control plant, equipment, and worker interaction

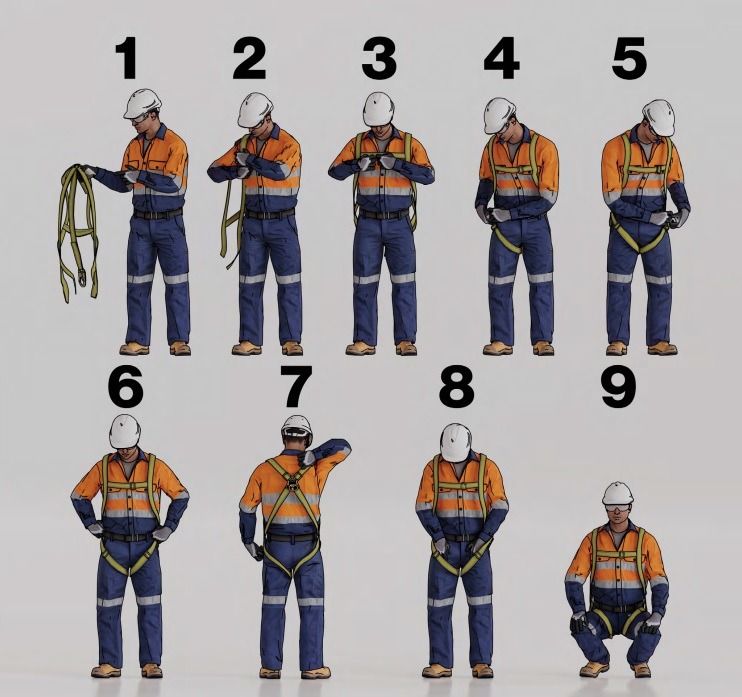

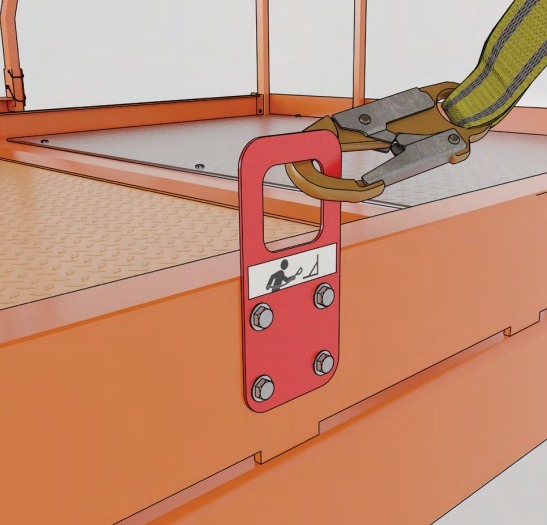

A full body safety harness is worn by every person on the platform of a boom-type EWP or vertical mast EWP fitted with a jib. This is to help control the risk of:

- a fall from the platform, should the platform strike an object

- a fall from the platform, should the EWP platform levelling system fail, resulting in the platform tilting or inverting

- a person being catapulted out of the EWP, for example while travelling over uneven ground or over a terrain drop-off

A full body safety harness is generally not required for occupants of scissor-type EWPs because they are protected by the guard rail on all sides of the platform. A fully body safety harness should be worn for scissor-type EWPs when recommended by the manufacturer or otherwise indicated in the site-specific risk assessment.

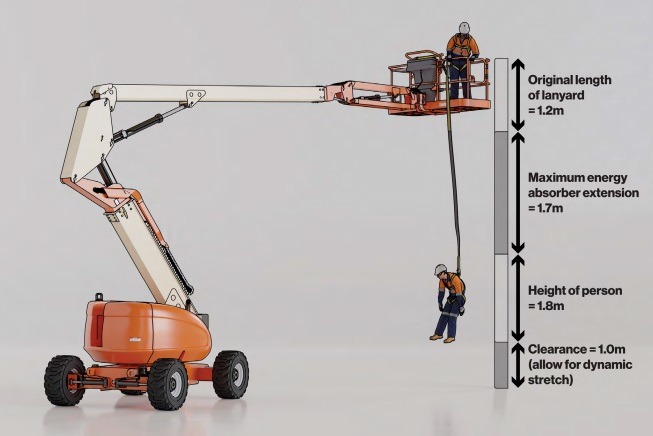

For relatively low height tasks, a site specific assessment is conducted to identify whether there is inadequate fall clearance, i.e. the potential for the fall arrest system (including energy absorber) to deploy and the occupant to still impact the ground.

If such a situation could occur, other methods for working at height such as using a mobile scaffold should be considered as a safer method for undertaking the task.

When a safety harness system is required, it complies with the AS/NZS 1891 Industrial fall arrest systems and devices series. When selecting lanyard lengths everyone on the platform should ensure that:

- the length of the lanyard is as short as possible, while still permitting the occupants in the EWP freedom of movement

- the operator is able to maintain both feet on the platform floor

Every person using a harness is competent in how to inspect, wear, use and secure a harness in accordance with the manufacturer’s instructions. Demonstration of this competency is provided (and a copy kept in the site files), and may include RTO training in Working at Heights RIIWHS204E, or a documented training record provided by the employer (if this training is delivered by a competent person).

Harnesses are inspected for defects prior to and after each use.

All personal equipment (including harnesses and associated equipment) are routinely inspected by a suitably competent person at six-monthly intervals.

Any harnesses that present with any defects are immediately removed from service, e.g.:

- Webbing: cuts, tears, scratching, grazing, excessive stretching, deterioration, rotting, mildew, Ultraviolet damage, heat damage (e.g. due to welding), exposure to corrosives or solvents

- Stitching: any fraying, cuts or tears which indicate potentially weak or damaged threads

- Snap hooks: hook or latch distortion (e.g. bending), cracks or forging folds, excessive wear at swivels or the latch pivot pin, open rollers, excessive movement of the latch, any broken, out of place or missing latch springs, soil or grime build up

- Buckles and adjusters: cracks, corrosion or other physical damage, missing parts, incorrect functioning, bent tongues, open rollers

- D-Rings: excessive movement of the D-Ring, cracks, signs of excessive wear, other physical damage

- Energy Absorber: signs of activation, tampering or damage

When a safety harness is required, a suitable anchor point is used such as the permanently fixed EWP anchor point

The surface incline is not exceeded with respect to the manufacturer’s operating instructions for that type of EWP

EWP movements only take place with the basket or work platform in the lowest position.

When movements are permitted by the manufacturer in the extended position, this may only take place in a designated exclusion zone and with spotters to eliminate the risk of collision with other plant, people and objects.

EWPs are not used as a material hoist. Materials to be installed that are with the worker in the EWP basket should fit inside the confines of the platform and still facilitate access, emergency egress and not compromise the operation of the controls.

If an EWP is to be moved through a doorway or restricted opening, the operator will exit the basket and operate controls from the ground, moving the EWP from outside of the work platform.

A safety observer will be used on the other side of the doorway to alert people to stay clear of the EWP

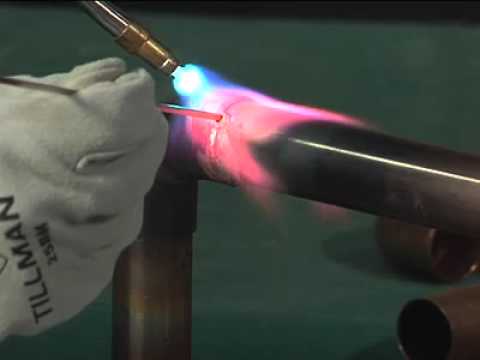

Firefighting equipment is available within EWP baskets/cabins where hot works are being performed, and at the completion of works a 30 minute firewatch is completed and verified on the Hot Work Permit.

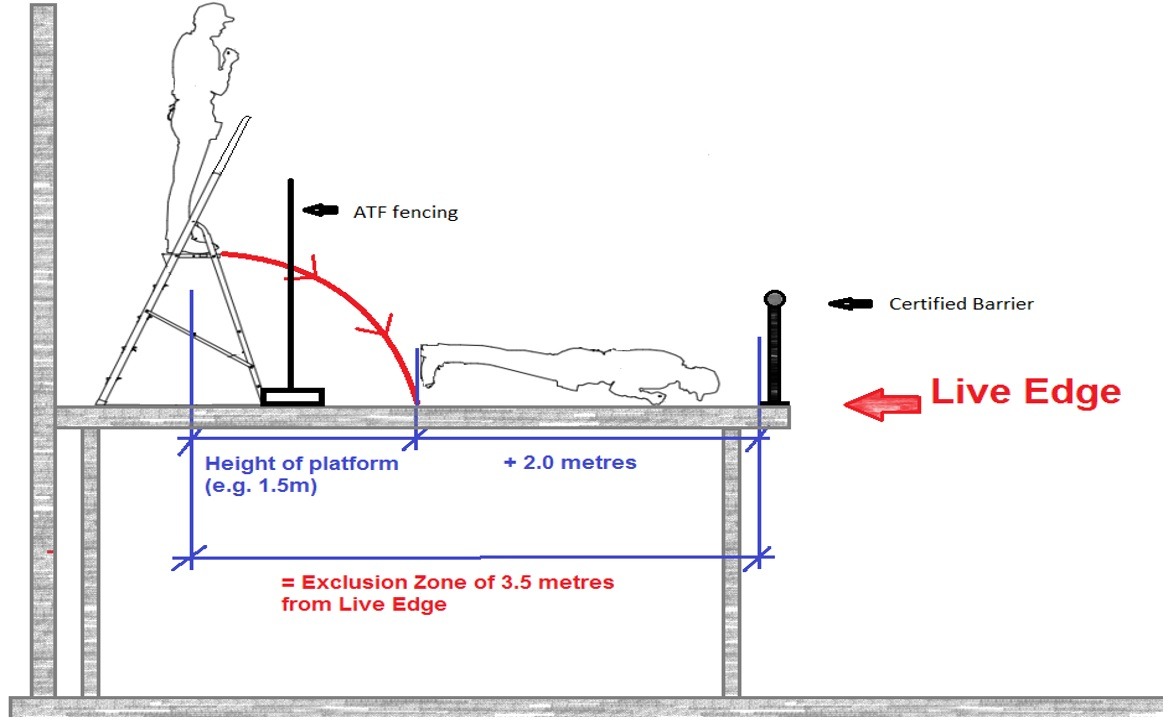

When EWPs are being used in the vicinity of a live edge (e.g. stair penetrations, kerb and channel, external building perimeters, change of levels), controls are in place to keep the EWP a safe distance from the edge, i.e. wheel stops, tethering, certified barriers.

Battery powered EWPs are recharged in a designated area located away from temporary construction switchboards.

The floor or ground load-bearing capacity have been verified in writing by a structural engineer (or geotechnical engineer where appropriate), and EWPs are parked for charging with a separation distance that avoids overloading the ground support structures.

Combustion type engines are only operated outdoors.

If operation of a combustion engine EWP is required in an enclosed or internal environment, adequate mechanical ventilation and air exchange must be implemented and monitored through consultation with a licensed Occupational Hygienist.

Refuelling of combustion engine EWPs is performed in a designated refuelling area. The work method is clearly addressed within the contractor’s SWMS.

An SDS for the fuel is provided to the SHAPE Project Team, and the product is entered into the Hazardous Chemicals Register after the completion of a Hazardous Chemical Risk Assessment which is signed by all workers involved in the refuelling works.

Suitable spill kits are located at the refuelling zone.

Emergency Preparedness and Incident Response planning is essential to ensure that all SHAPE projects and offices are adequately prepared and resourced in case of an emergency or in case any workers require rescue.

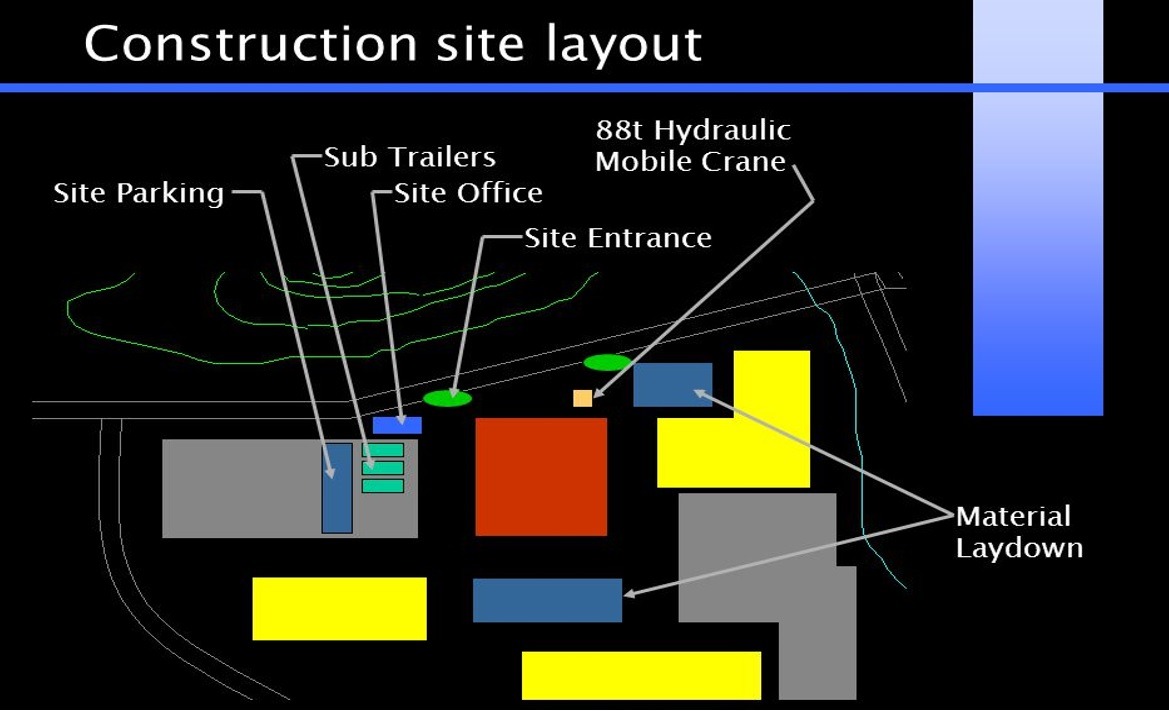

During pre-construction, the project team reviews emergency planning and incident response requirements for inclusion into the project Risk Register and Project Delivery Plan.

NB: this will include the Building Management Emergency Response protocols.

Projects with a higher risk profile are encouraged to use the separate Project Emergency Response Plan to sufficiently address the higher legal requirements for emergency preparedness (e.g. the use of Tower Cranes or mast climbers, cladding replacement works, where there is a risk of worker suspension at height, difficult or restricted access and egress situations, multi-level or spur / hung / cantilevered modular scaffolds, use of forklifts, civil works with the risk of powered mobile plant rollover).

The project’s designated emergency personnel are inducted into the site-specific emergency response procedures / plans by signing either the Project Delivery Plan or Project Emergency Response Plan, as appropriate

The nearest available health or medical services have been identified,and they have been contacted to establish their ability to assess or treat work-related injuries.

NB:

- Isolated sites (more than 20 minutes from appropriate medical services) may require further due diligence and planning to respond to medical emergencies

- For shift work, consideration must be given to the medical facility’s opening hours

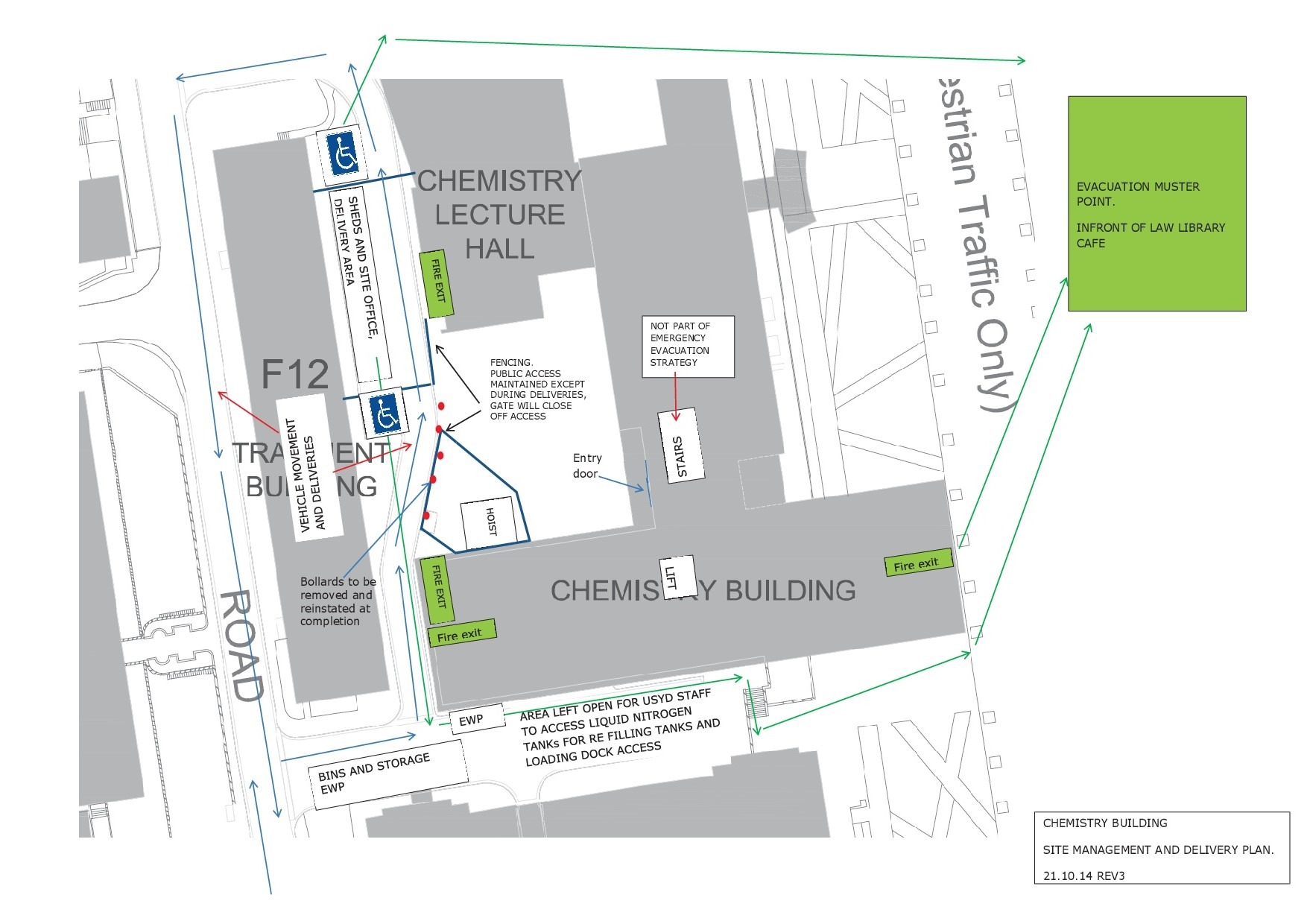

Emergency Evacuation Diagrams have been created using the Evacuation Diagram Tool.

Emergency Evacuation Diagrams are displayed on site, in accordance with the Guide to the Evacuation Diagram Tool.

Emergency response procedures are documented to all workers and visitors within the Site Induction.

Emergency Evacuation training is completed within the first 2 weeks of commencing the project, and then every 3 months thereafter.

Task-specific Emergency Response Plans are prepared and implemented for all high risk activities or activities requiring potential rescue resources and equipment.

The nominated warden has completed a relevant training course through a Registered Training Organisation (RTO).

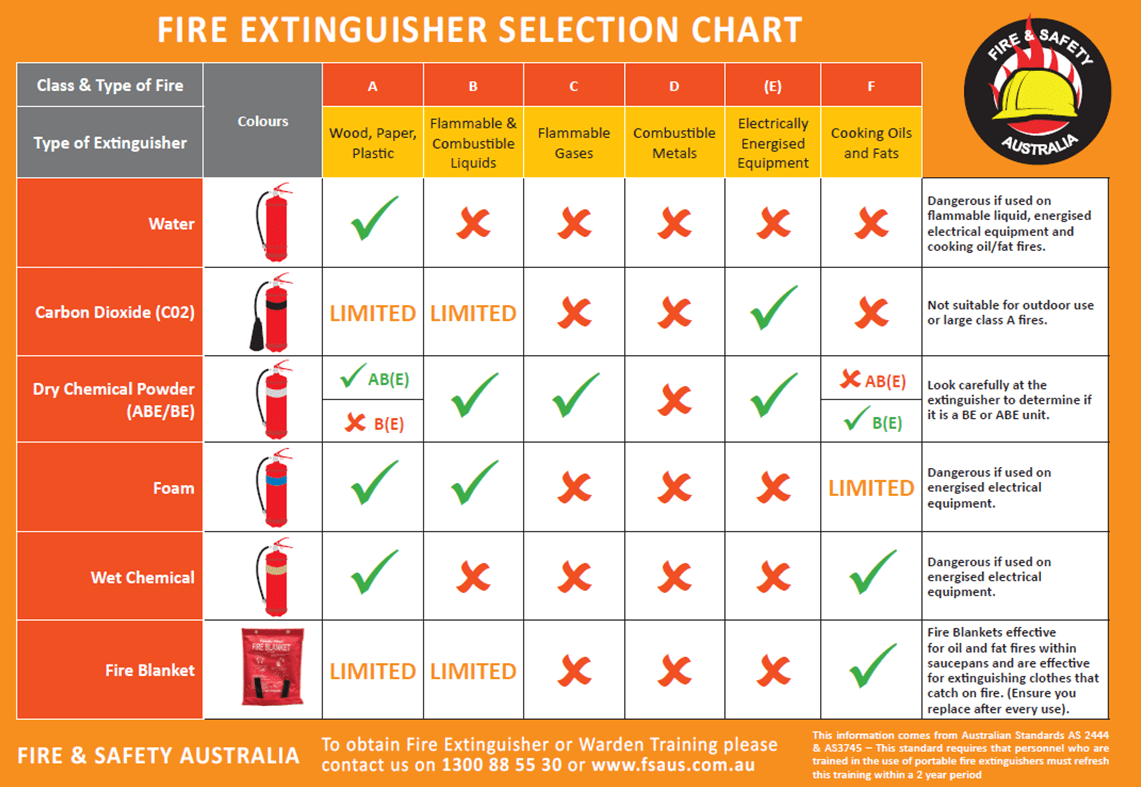

Risk Assessment of the project emergency response hazards within the Project Risk Register will determine the site’s firefighting equipment requirements, for example:

- Low Risk Environments – retain the existing base building equipment, OR provide at least 1 Class A (General) and 1 Class E (Electrical) extinguisher per floor

- Medium to High Risk Environments – provide 1 extinguisher for each temporary construction switchboard on site, i.e. if there are 5 temporary construction switchboards per floor then there should be 5 extinguishers per floor – the class/size of extinguishers required will be determined via risk assessment in consideration of the nature of work and combustibles on site

Note: it is not ideal to position fire extinguishers at/on Electrical Switchboards themselves – ideally they should be positioned in a highly visible and accessible standalone location

- Hot Works – A separate portable fire extinguisher of the appropriate class/size (provided by the subcontractor) is required in the vicinity of all hot works

Note: it is not ideal to position fire extinguishers at/on Oxy-Acetylene trolleys themselves when the Oxy-Acetylene kit is in use

Where hot works activities are undertaken, nominated personnel are competent in the use of fire fighting equipment. The nominated person has demonstrated that they understand how to select and use the designated fire fighting equipment.

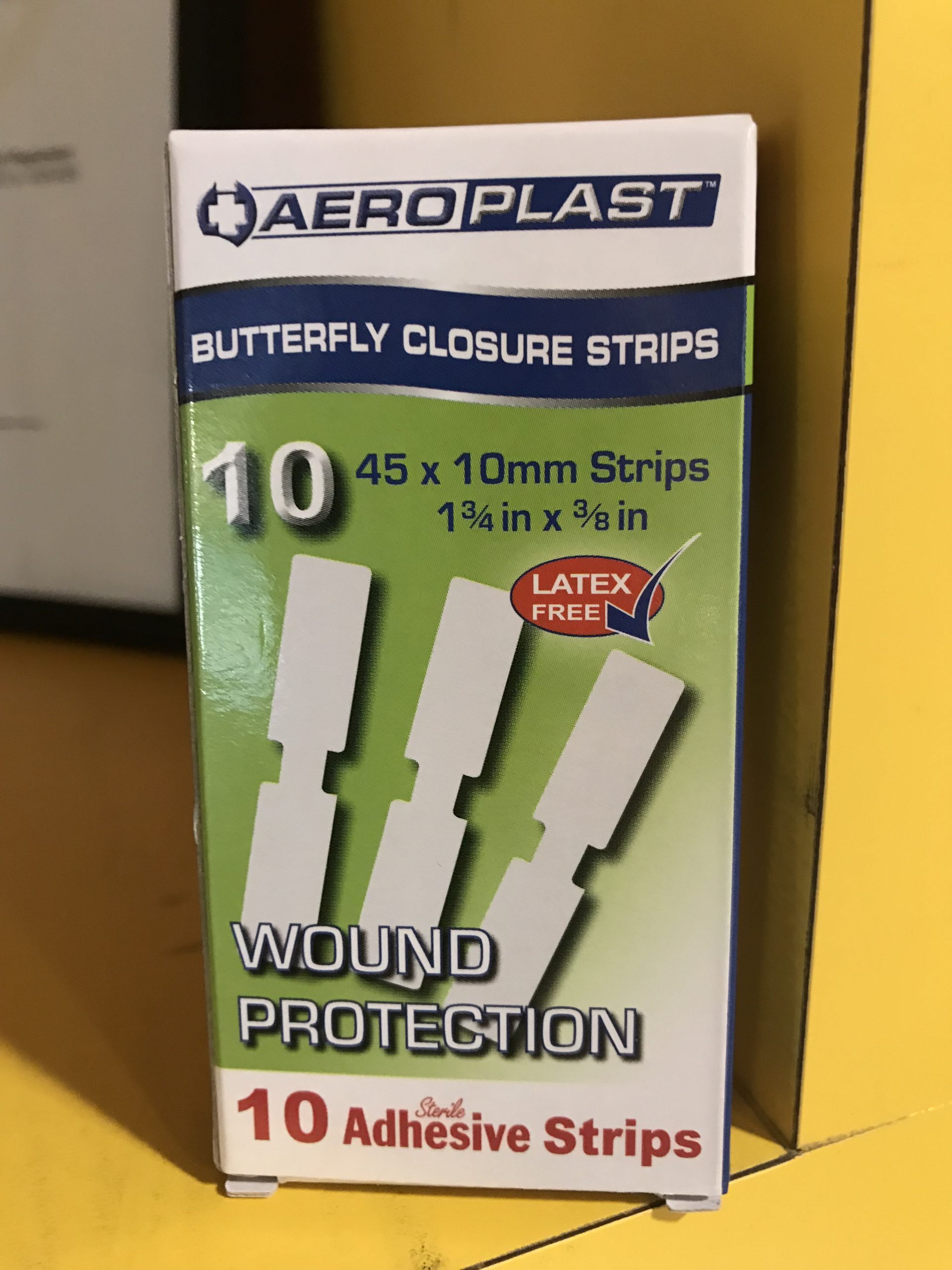

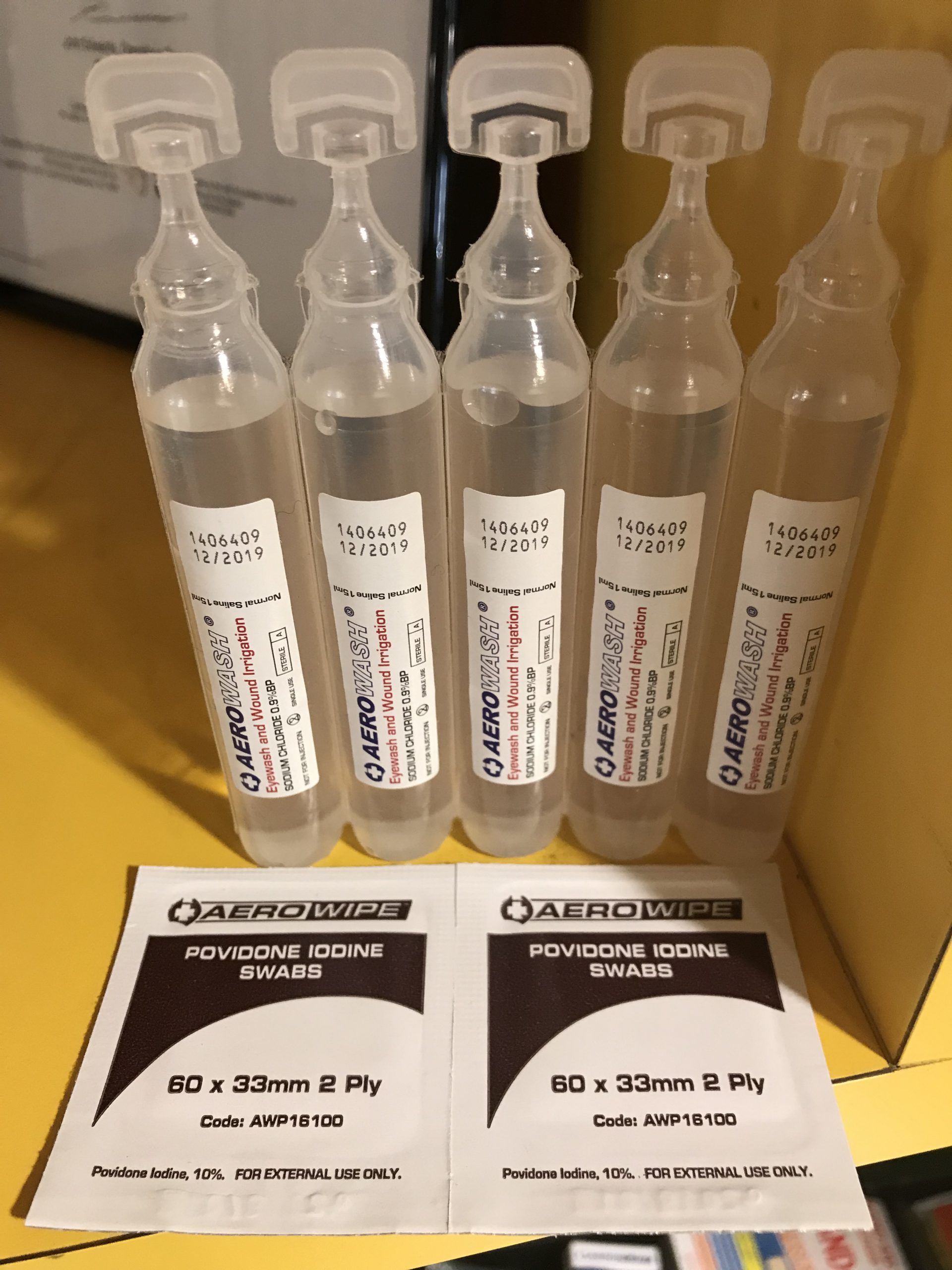

Nominated first aid officers have current qualifications

First aid requirements for the project have been assessed by a qualified First Aider, are documented within the Project Risk Register and Project Delivery Plan, and are based on site-specific risks including the scope of works, environment and location. This risk assessment is developed with reference to the relevant state/territory First Aid Compliance Code or Code of Practice. Where the use of hazardous chemicals is required, additional first aid supplies may need to be provided by SHAPE or the subcontractor.

A First Aid Room is provided for sites that will reach a peak of 100 workers or more. The following items are provided inside the First Aid Room:

- A sink and wash basin with hot and cold water (unless this can be provided within easy access from the First Aid room)

- A work bench or dressing trolley

- Cupboards for storing medicaments, dressings and linen

- A hazardous waste container or bio-hazard bags for soiled dressing

- A sharps disposal system

- Electric power points

- Hygienic hand cleanser and disposable paper towels

- An examination couch with waterproof surface, pillow, blanket and disposable sheets

- An upright chair

- An examination lamp with magnifier

- A bowl or bucket (minimum 2 Litres capacity)

- A chair and a table or desk

- Names and contact details of first aiders and emergency organisations on the SHAPE First Aid contacts poster

- A first aid kit appropriate for the workplace, including a resuscitation mask and face googles

- A stretcher

- An Automated External Defibrillator (also known as an AED or simply a “defibrillator”)

A first aid room should:

- Be located within easy access to toilet facilities and a sink with hot and cold water (where this is not provided in the room itself)

- Offer privacy via screening or a door which remains easily accessible to emergency services, with a minimum door width of 1 metre for stretcher or wheelchair access

- Be well lit and ventilated

- Be large enough for its purpose (e.g. 14 square metres as a guide)

- Have an entrance that is clearly marked with the SHAPE First Aid contacts poster

Arrangements have been made to ensure first aid kits are regularly re-stocked.

Emergency Exits are clearly signposted and operational.

Where there are any changes to emergency exit requirements, these are communicated through a Toolbox Talk and the Site Induction.

Emergency Evacuation Diagrams are updated to reflect these changes.

Any action to the smoke detection, sprinkler, hydrant or fire hose reel systems that will be affected throughout the project have been communicated to all parties on the project via Toolbox Talk and Site Induction.

Sprinkler heads remaining active have been highlighted to improve visibility. Sprinkler heads at risk of damage have been capped or caged.

Control measures to manage damage to sprinkler heads have been risk assessed, with the controls implemented and communicated via Toolbox Talk and the Site Induction.

The building emergency warning system is operational throughout the project, OR an alternative warning system has been implemented (e.g. horn system, nurse call, etc.)

Risk Assessment of the project emergency response hazards (within the Project Risk Register and Project Delivery Plan), completed by a SHAPE Site Representative who has successfully completed a Fire Warder Training course through an RTO, will determine the site’s firefighting equipment requirements, for example:

- Low Risk Environments – Retain the existing base building equipment, OR provide at least 1 Class A (General) and 1 Class E (Electrical) extinguisher per floor

- Medium to High Risk Environments – Provide 1 extinguisher for each temporary construction switchboard on site, i.e. if there are 5 temporary switchboards per floor then there would be 5 extinguishers per floor – the class/size of extinguishers required will be determined via risk assessment in consideration of the nature of work and combustibles on site (note – it is not ideal to position fire extinguishers at or on Electrical Switchboards themselves – ideally they should be positioned in a highly visible/accessible standalone location)

- Hot Works – A separate portable fire extinguisher of the appropriate class/size (provided by the subcontractor) is required in the vicinity of all hot works (note – it is not ideal to position fire extinguishers at or on an oxy-acetylene trolley when that oxy-acetylene kit is in use)

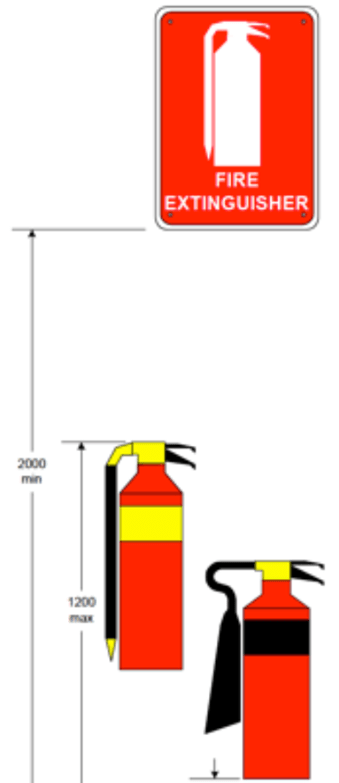

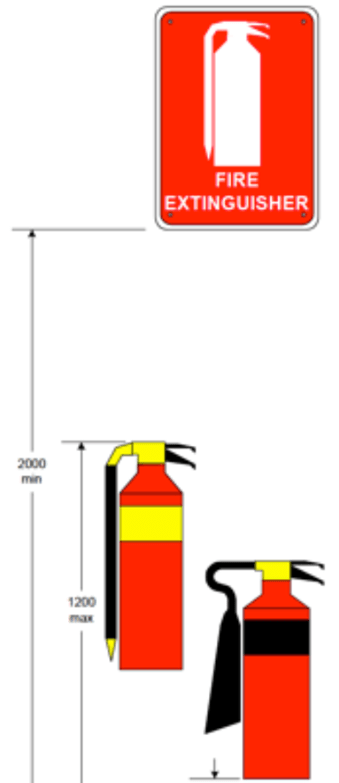

Fire extinguishers and their signs are mounted in accordance with AS2444. This includes, but is not limited to:

EXTINGUISHER MOUNTING WALL BRACKET HEIGHTS

- A minimum of 100mm from the floor to the bottom of the extinguisher (fire extinguishers must not be situated on the ground)

- A maximum of 1200mm from the floor to the top of the extinguisher handle

LOCATION AND DISPLAY OF SIGN

- Minimum of 2000mm above floor level

- At a point that makes them most apparent to a person of average height & visual acuity

- The extinguisher or extinguisher sign shall be clearly visible for up to 20 metres on approach

- The size of the sign shall be determined by location on and distance at which the sign must be legible

- A minimum of one Pictorial or location sign must be provided above or adjacent to an extinguisher, even if indicating the location of multiple or a mixed group of extinguishers

- The extinguisher and fire point location signs shall have a symbol, border and letters in white on a red field, complying with Australian Standard (AS) 2700

- Australian Standard (AS) 2444 Portable Fire Extinguishers and Fire Blankets – Selection and Location provides comprehensive and specific information

- It is also recommended that you have a square instruction disc (ID – SIGN) directly above the extinguisher wall bracket. Even though these details are on the portable fire extinguisher they can get covered up with stickers, etc. blocking the instructions

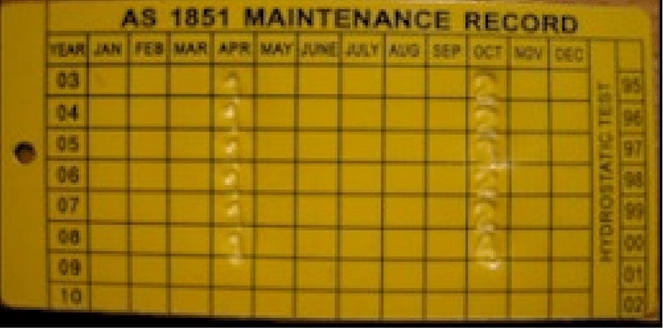

Firefighting equipment is within test date.

Q: How do I understand the tag? A numeric symbol is marked in the month and year for each inspection and certification.

Q: What do the numeric symbols stand for?

1 – six monthly inspection

2 – yearly inspection

3 – (this numeric symbol is no longer used, the previous Australian Standard has been superseded)

4 – five yearly inspection (pressure testing)

5 – after use service

Should a critical incident occur, all SHAPE project stakeholders and senior leadership team members review and implement their actions and communication protocols as outlined in the Critical Incident Response guide.

SHAPE is committed to promote sustainability as an integral part of each project, to encourage better environmental practices among the suppliers and subcontractors we engage, and establish measurable objectives and targets that address our environmental impact.

During pre-construction, the project team reviews the scope of works with respect to environmental aspects and impacts for inclusion into the Project Risk Register and Project Delivery Plan.

The project Site Induction includes environmental controls specific to the project:

- Spill control

- MDF cutting

- Ventilation – natural or mechanical

- Dust/sediment suppression

- Stormwater management

- Waste water management

- Noisy works

- Hazardous Chemicals (refer to the Hazardous Chemicals SMS)

- Waste Management

- Flora and fauna

Subcontractor SWMS include environmental aspects, impacts and control measures, including requirements for the handling, storage, use and disposal of Hazardous Chemicals in accordance with the SDS.

Spill kits are:

- Fully stocked

- Appropriate for the scope of works

- Positioned in the area of risk

- Sign posted

Workers are aware of spill control measures, as outlined in the product’s SDS.

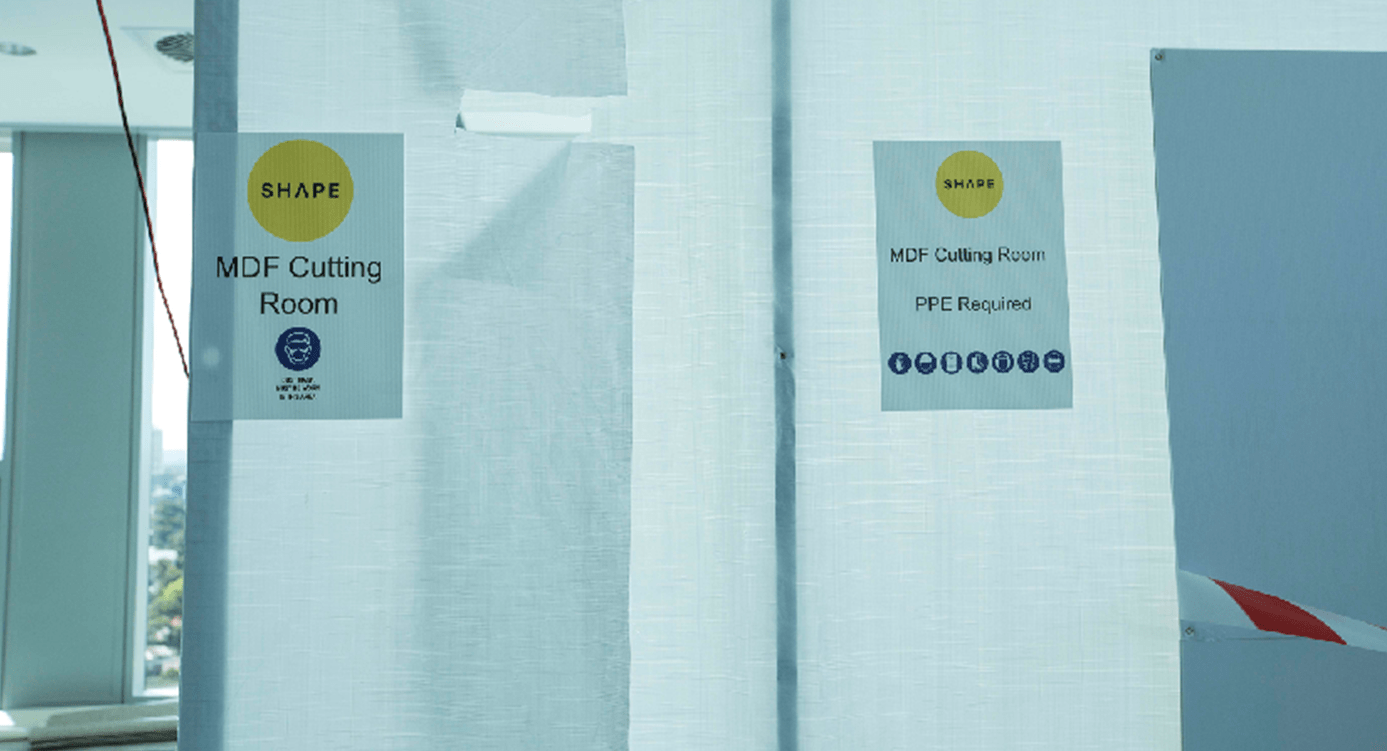

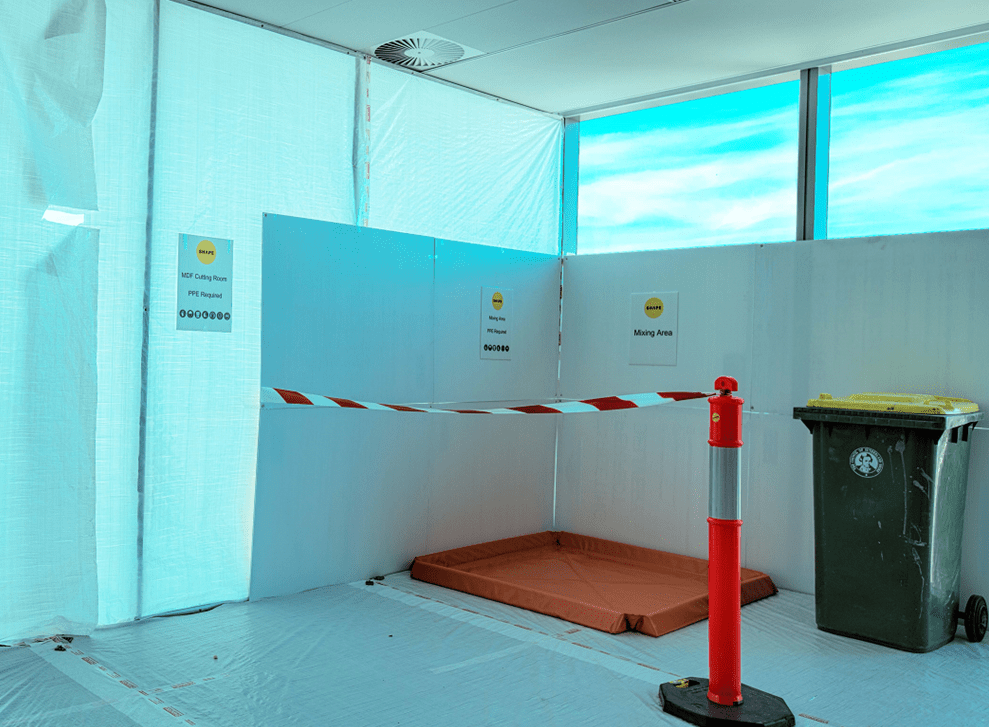

MDF cutting:

- Wherever possible, alternative products to MDF are to be used (e.g. Emissions Zero or EO board, Hoop Pine)

- If MDF is to be used, MDF cutting is to be completed off site wherever possible

- If MDF is to be cut or sanded on site, an MDF cutting room has been established in accordance with the Medium Density Fibreboard (MDF) Procedure.

- MDF cutting rooms are identified with the following signage at the entrance:

- MDF Cutting Room warning signage

- Mandatory PPE signage

- Workers are to wear PPE in accordance with the product SDS

- Cutting tools will be fitted with a HEPA-vacuum extraction system

- The room is kept tidy at all times, and dust is bagged for disposal

Ventilation:

- Where natural ventilation is not adequate for the site, mechanical ventilation is used, e.g. extraction fans, pedestal fans, portable air conditioning units, etc.

- Where existing mechanical services are operational, additional filter media will be installed over air intakes to prevent contamination

All activities that may cause dust or release airborne fibres have control measures in place to prevent contamination of common air spaces, impacts on other trades and offsite impacts.

Dry sweeping is not permitted on SHAPE sites.

Dust controls may include:

- Water suppression

- Negative pressure air zones

- Use of extraction systems with in-built filtration

- Tool accessories

- Wet brooming

- Vacuum equipment

- Limiting the use of exhaust emitting equipment

- Banning excessively smoky vehicles and equipment

- Enclosed areas for dedicated dust generating activities

- Air quality monitoring

- Conducting work out of normal hours

- Encapsulation or treatment of exposed synthetic mineral fibre

For external works:

- Water trucks

- Hydroseeding / spraygrass

- Stockpile encapsulation

- Rumble grids / shakedown tracks are in place for vehicle access and egress

- A road maintenance cleaning program is in place (e.g. street sweepers or similar)

Consideration is given to the potential introduction of contaminated soils, fill and mulch products (which are often man-made products constructed from recycled or waste material). Examples of possible contamination include asbestos, lead, PFOS/PFAS, acid sulphates, other chemicals, fire ants, plastics, glass, etc.

Soil, fill and mulch products are only procured from reputable suppliers, the materials are visually inspected upon delivery for any signs of visible contamination, and if in doubt project teams will consult with an Occupational Hygienist to determine a suitable and site-specific inspection and sampling process.

Note: for schools and public infrastructure projects, always seek proportionate sampling and testing processes from an Occupational Hygienist as the material arrives to site.

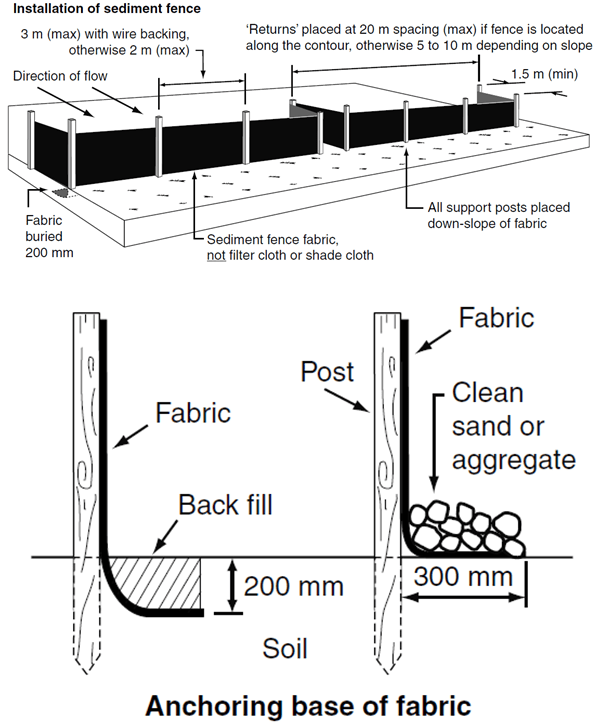

Stormwater management controls are implemented when appropriate:

- Filtration media

- Filtration socks

- Hay bales

- Silt barriers/fences

- Tarping of waste containers or stockpiles in adverse weather conditions

Waste water management controls are implemented when appropriate:

- Designated and bunded wet trade mixing areas

- Wash out systems (e.g. Dulux Envirowash System, Resene WashWise, or similar)

- Sediment tanks (e.g. for plaster, cement, tiling products, etc.)

- Waste water is disposed of in accordance with the SDS, and local council or Environmental Authority requirements

Noisy works controls are implemented when appropriate:

- Work methods are selected which eliminate or minimise noise generation as much as practical (e.g. placing materials instead of dropping, exhaust silencers are used, sound rated rooms, use of acoustic panelling and other noise dampening materials, cutting rooms, etc.)

- Plant and Equipment are turned off when not in use

- Works are in accordance with building management and Development Approval (DA) constraints

- Noisy works are scheduled at a time that reduces exposure to other workers

- Where possible, workers are excluded from noisy work locations

- Neighbours and stakeholders are notified in advance of planned noisy works activities

- Hearing protection must be worn by workers and others in the vicinity of the noise

- Noise monitoring and assessment is conducted for repetitive noisy works

Monitoring and inspections take place via site walks and Procore Hazard Observations

Waste management controls are in place and effective:

- Waste management strategies are communicated as part of the Site Induction

- There is an adequate number of bins

- The size and type of bins are appropriate for the type of waste generated by the scope of works

- Bins are not overflowing

- There is a bin exchange or turnover strategy in place, which is communicated at induction

- A waste tracking and separation plan is in place (NB this is mandatory for all Green Star projects)

- A housekeeping strategy is in place

Paint and/or hazardous products are appropriately managed (i.e. storage, signage, handling and disposal are in accordance with the SDS).

Posters or signage highlighting environmental initiatives (e.g. recycling) are displayed on site.

Vehicle movements and parking are managed to minimise environmental impact on the neighbourhood and other stakeholders.

Sediment fencing is in place where required

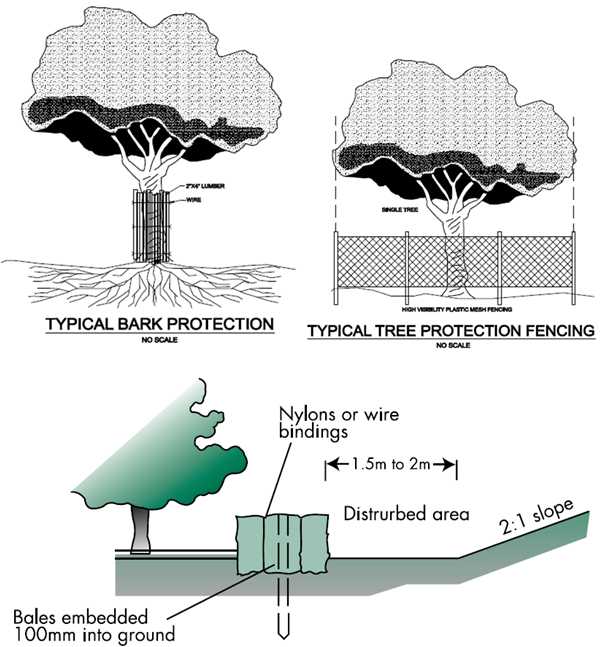

Flora and fauna controls are implemented when appropriate:

- Garden beds are protected

- Trees are adequately protected